-

Highlight

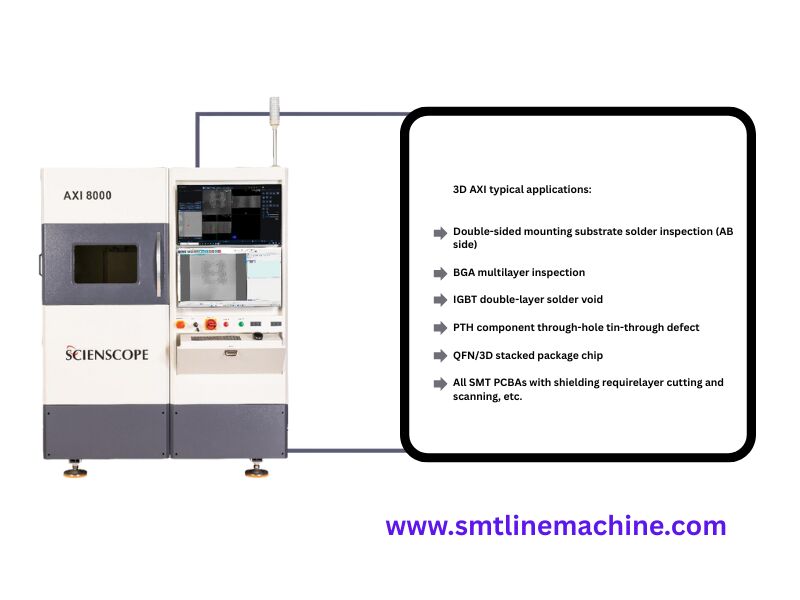

Scienscope X-RAY 3D AXI 8000 machine

,fully automatic SMT line machine

,3D AXI X-RAY inspection system

-

Brand NameScienscope

-

Model NumberX-RAY 3D AXI 8000 Fully Automatic

-

Minimum Order Quantity1 set of machine or mixed order is also acceptable

-

PriceNegotiable

-

Packaging DetailsStandard export boxes and sturdy hardwood packages are both options

-

Delivery Time5-8 Working days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union,MoneyGram

Scienscope X-RAY 3D AXI 8000 Fully Automatic

The Scienscope X-RAY 3D AXI 8000 Fully Automatic is an entirely automated 3D X-ray inspection system that utilizes sophisticated CT (Computed Tomography) technology. This advanced scanner provides a complete 360-degree view within your electronic components without requiring disassembly.

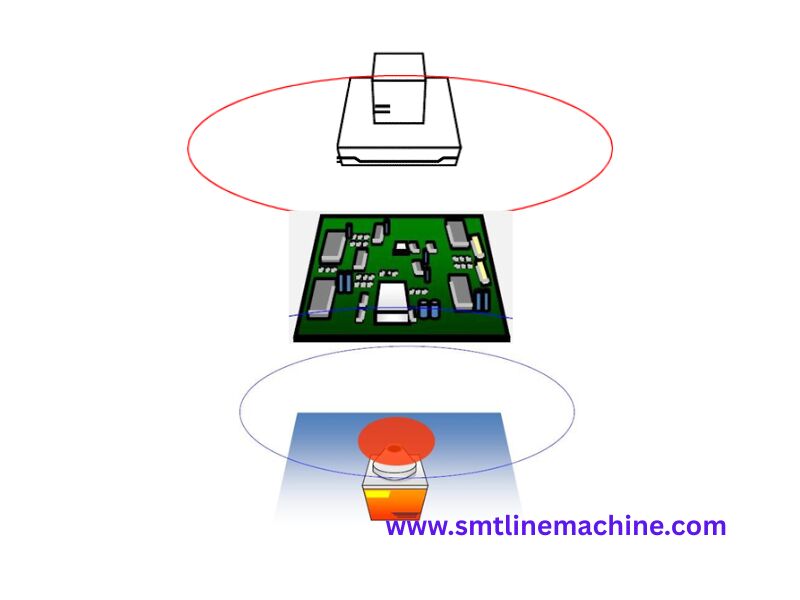

The system captures projection mappings by rotating around the object in a full circle, then employs edge-scan and 3D analysis techniques to reconstruct all collected data. This creates a digital 3D replica that allows examination of internal structures from any perspective to identify even the tiniest defects.

3D Automated X-ray Inspection (AXI) represents a cutting-edge approach in electronics manufacturing, designed to deliver comprehensive evaluations of Printed Circuit Boards (PCBs). Unlike conventional 2D X-ray methods, 3D AXI leverages computed tomography (CT) to produce detailed, three-dimensional visualizations of the internal composition of electronic components and solder connections. This sophisticated technique identifies defects undetectable via 2D X-ray, including voids, misalignments, and inadequate solder application.

| Parameter Category | Specification | Details |

|---|---|---|

| X Illuminant | Light tube voltage, current | 130KV 300uA |

| Maximum Output | 39W | |

| FPD | Resolution ratio | 50um |

| Frame Rate | 1x1 9fps, 2x2 18fps | |

| Pixel Size | 2340x2882 | |

| CCD Camera | Pixel | 2.3 megapixel |

| Function | Scan the barcode | |

| CT Parameters | Resolution ratio | 5um |

| Number of Projections | 32,64,120 | |

| Shooting Angle | 60°, 90° | |

| Maximum Number of Layers | Unlimited (recommended <300) | |

| Test Parameters | Feed height | 85mm on top, 20mm on bottom |

| Delivery Direction | Left in, right out | |

| PCB Size | 100x50-400x400 | |

| Circuit Board Thickness | ≥0.5mm | |

| Height of Test Object Components | 85mm on top, 20mm on bottom | |

| Object Weight | ≤5KG | |

| FOV Size | 58x70mm (25μm precision), 11x14mm (5μm precision) | |

| Plate Bending Correction | Hardware correction | |

| Safety | Radiation | 1μSv/H |

| Safety Interlocking | Available | |

| Environmental Requirements | Working Temperature | 0-40℃ |

| Working Humidity | 40%-60% | |

| Working Power Supply | 220V | |

| Aggregate Capacity | 2KW | |

| Pressure Requirements | 0.4-0.6 MPa | |

| Load Capacity Requirements | 1.5T/㎡ | |

| Device Appearance | Size | 1625mm*1465mm*1905mm |

| Weight | 2.5T |

- Extensive Flaw Detection: Identifies a broad spectrum of defects including solder joint integrity issues, component displacement, air pockets, and concealed electrical short circuits.

- High-Resolution Imaging: Employs advanced X-ray cameras and sophisticated algorithms to secure detailed imagery for critical insights into PCB internal architecture and robustness.

- Streamlined Efficiency and Usability: Equipped with intuitive interfaces and user-friendly software for straightforward operation and rapid inspection cycles to boost production throughput.

- Automated Calibration: Features automatic adjustment of inspection parameters to accommodate production changes, minimizing setup losses and manual recalibrations.

- Complete 3D X-Ray Analysis: Offers full 3D reconstruction for thorough assessment.

- Non-Invasive Assessment: Allows inspection of circuit boards without inducing damage.

- Adaptable Layer Selection: Permits selection of necessary layers for examination.

- Customizable Resolution: Enables adjustment of resolution based on component dimensions and solder balls, ensuring precision.

- Accelerated Edge Scanning: Incorporates rapid scanning and reconstruction technologies.

- Broad Ray Cone Angle: Delivers superior longitudinal resolution for enhanced inspection.

- Inspection of Surface Mount Technology (SMT) and Through-Hole Components: Guarantees quality of solder joints and precision of component placement in both SMT and through-hole assemblies.

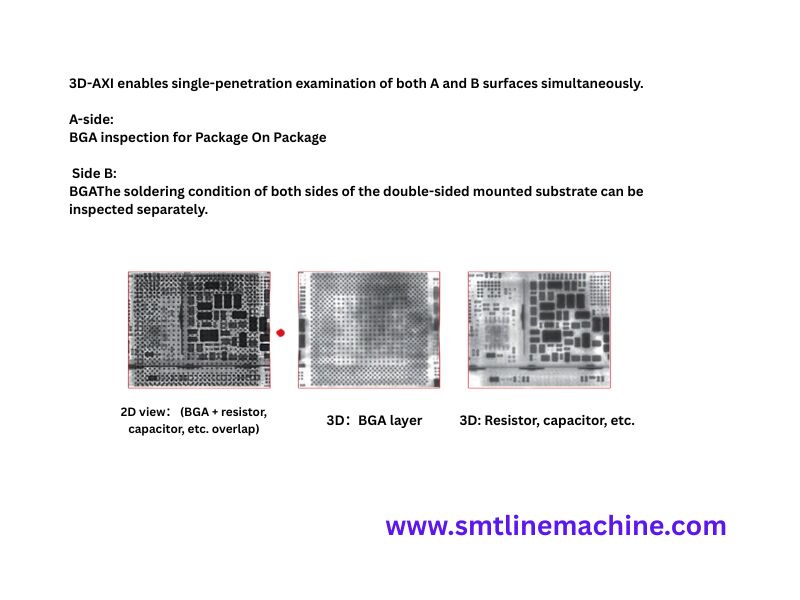

- Examination of Ball Grid Arrays (BGAs) and Press-Fit Connectors: Detects faults in BGA solder joints and verifies integrity of press-fit connections.

- Dual-Sided PCB Analysis: Evaluates both faces of double-sided PCBs to ensure uniform quality standards.

- Computed Tomography (CT): Utilizes X-rays to create sectional images compiled into 3D representations.

- High-Definition X-Ray Cameras: Capture intricate images of internal structures of electronic parts.

- Automated Anomaly Recognition (AAR): Employs software algorithms to automatically identify defects through image analysis.

- Real-Time Oversight and Management: Empowers operators to supervise inspection processes and implement adjustments as required.

- Enhanced Quality Assurance: Identifies defects early in production, preventing circulation of defective products.

- Amplified Productivity: Automates inspection workflow, reducing manual labor and accelerating production speeds.

- Economical Benefits: Lowers waste and rework needs by spotting defects before they escalate.

- Heightened Dependability: Confirms electronic goods adhere to highest quality and reliability benchmarks.

Scienscope X-RAY AXI 8000 3D AXI systems are indispensable for upholding the quality and dependability of electronic products. By supplying comprehensive three-dimensional imagery of internal structures, these systems enable manufacturers to uncover defects that might otherwise go unnoticed.

For inquiries, please contact us at:

Phone: +8613537875415

Email: Lizzy@smtlinemachine.com

Address: Xintian Industrial Area, Baoan, Shenzhen City, China

- Delivery: 5-8 business days (varies based on order quantity)

- Minimum Order: Single machine or mixed orders accepted

- Transportation: Bulk shipping or container shipment based on order size

- Payment Terms: L/C, D/A, D/P, T/T, Western Union, MoneyGram

- Price: Negotiable for best value

- Packaging: Standard export boxes or robust hardwood packages for safe delivery