-

Highlight

Scienscope X-ray inspection machine

,X2000 SMT line X-ray viewer

,X-ray machine for SMT assembly

-

Brand NameScienscope X-ray

-

Model NumberX-ray View X2000

-

Minimum Order Quantity1 set of machine or mixed order is also acceptable

-

PriceNegotiable

-

Packaging DetailsStandard export boxes and sturdy hardwood packages are both options

-

Delivery Time5-8 Working days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union,MoneyGram

Scienscope X-ray View X2000

Scienscope X-ray View X2000

The Scienscope X-ray View X2000 is a reliable and powerful X-ray inspection system meticulously engineered for the detailed examination of a wide array of components, with a particular emphasis on printed circuit boards (PCBs). This system excels in critical tasks such as PCB inspection and BGA inspection, providing advanced capabilities at a competitive price point.

The Scienscope X-ray View X2000 is an indispensable tool for industries demanding the highest levels of quality and reliability. With this X-ray system, users can perform thorough PCB analysis and BGA analysis, enabling the identification of defects, assessment of assembly quality, and assurance of product reliability without the need for destructive disassembly.

The system's non-destructive testing approach saves time and resources while providing comprehensive insights into the internal structure of components. High-resolution imaging capabilities ensure that even the smallest anomalies are detected, preventing potential failures and ensuring optimal performance.

Technical Specifications

| Whole Machine | |

|---|---|

| Model | ViewX2000 |

| Weight | 1100KG |

| Size | L1180*W1360*H1650(mm) |

| Power Supply | 50-60Hz/220V |

| Air Supply | Not Required |

| Total Power | 1.2KW |

| X-ray System | |

| X Tube Max Voltage | Closed tube 90KV |

| X Tube Angle | 80° |

| X Tube Focal Spot | 5μm |

| Imaging | |

| Main Camera Type | HD digital flat panel |

| Effective Imaging Area | 146*115mm |

| Pixels | 96μm |

| Main Camera Resolution | 1536*1184 |

| External Function | |

| Barcode | Optional |

| Link MES System | Optional |

| Safety | |

| Auto Safety Access Control | Door cannot be opened when X-ray is activated (electromagnetic induction) |

| Radiation Safety Standard | ≤1μsv/h |

Key Applications Across Industries

- Electronics: Essential for high-resolution BGA inspection and PCB inspection, ensuring the quality of electronic assemblies by examining components and solder joints with unparalleled clarity.

- Material Analysis: Capable of inspecting various materials, including aluminum, plastics, and ceramics, to identify structural defects, porosity, and other internal inconsistencies that could compromise the integrity of the material.

- Aerospace and Automotive: Guarantees the reliability of critical components through rigorous X-ray examination, ensuring that parts meet stringent safety and performance standards in demanding applications.

- Pharmaceuticals: Checks product consistency and detects foreign materials, ensuring product safety and adherence to strict regulatory requirements. The X2000 helps maintain the highest standards of quality in pharmaceutical manufacturing.

- Counterfeit Detection: Plays a crucial role in identifying counterfeit components, protecting product authenticity, and preventing the integration of substandard parts into critical systems.

Key Features for Superior Performance

- High-Resolution Imaging: A micro-focus X-ray tube (up to 90KV, 5-micron spot) and a high-definition digital flat panel detector (1536 x 1184) combine to deliver exceptionally clear and detailed images, allowing for precise defect identification and analysis.

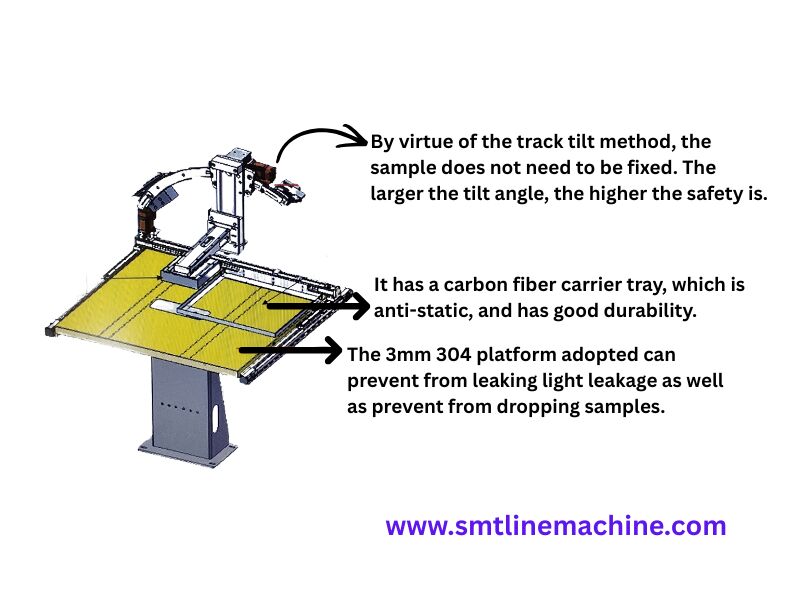

- Tilting: Offers angled views for enhanced inspection of hard-to-reach areas and complex geometries, providing a more comprehensive understanding of the internal structure of components.

- Large Inspection Area: A spacious table (550mm x 530mm) accommodates a wide range of sample sizes, providing flexibility for inspecting various components and assemblies.

- Software: User-friendly software facilitates automated image capture, measurement, and analysis, including specialized BGA void detection tools. The intuitive interface simplifies the inspection process and enhances productivity.

- Safety: A robust enclosure ensures complete radiation containment, guaranteeing operator safety with radiation levels maintained at ≤ 1 μSv/H.

- Display: A 24'' 2K display provides enhanced viewing clarity, allowing operators to scrutinize images with greater detail and accuracy.

- Emergency Stop: An easily accessible emergency stop switch enables quick response to any unforeseen issues, ensuring a safe working environment.

- Sliding Door: A seamless side sliding door optimizes space utilization and contributes to a clean and organized workspace.

Key Advantages: Why Choose the X2000?

- Detailed Inspection: Delivers high-resolution images for precise defect identification, ensuring the quality of solder joints, component placement, and internal structures.

- Versatility: Adaptable to a broad spectrum of applications and industries, making it a valuable asset for diverse inspection needs.

- User-Friendly: Features an intuitive interface and automated functions that streamline the inspection process, reducing training time and improving efficiency.

- Cost-Effective: Provides advanced X-ray inspection capabilities at an affordable price point, offering exceptional value for your investment.

- Comprehensive Analysis: Equipped with software tools for detailed measurement and analysis, enhancing inspection accuracy and providing valuable insights into component quality.

About the Product

The Scienscope X-ray View X2000 is a reliable and efficient solution for anyone requiring detailed internal imaging and analysis. Its advanced features and user-friendly design make it an indispensable tool for quality control, research, and failure analysis.

Contact Information:

Phone: +8613537875415

Email: Lizzy@smtlinemachine.com

Address: Xintian Industrial Area, Baoan, Shenzhen City, China

Packaging and Delivery Information

Delivery: Expect your order to arrive within 5-8 business days, though this timeframe can vary based on the quantity ordered.

Minimum Order: We accept orders for a single machine or mixed orders to suit your needs.

Transportation: Products are shipped either in bulk or via containers, depending on the order size and destination.

Payment Terms: Flexible payment options are available, including L/C, D/A, D/P, T/T, Western Union, and MoneyGram.

Price: Prices are negotiable to ensure you receive the best possible value.

Packaging: We offer both standard export boxes and robust hardwood packages to ensure your order arrives safely and securely.