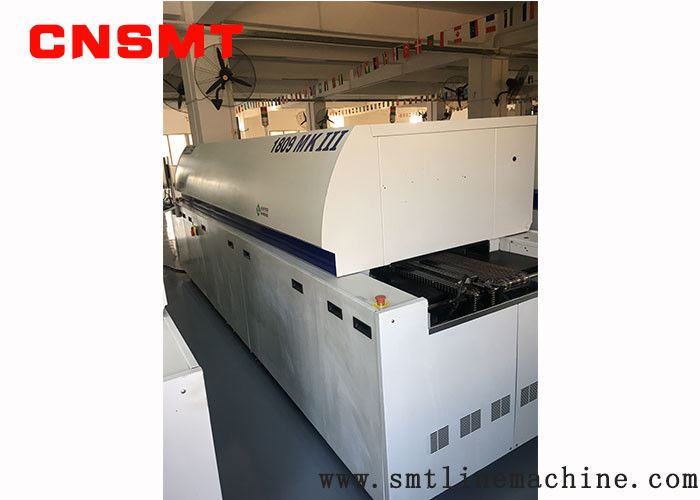

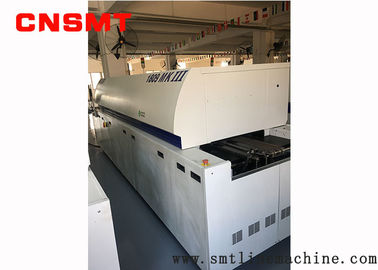

CNSMT Supply Heller Smt Production Line 1809MKIII 1809EXL Used Reflow Oven 9 Zone Heats 2 Cool Zone

-

Highlight

smt assembly equipment

,smt assembly machine

-

Product NameHELLER REFLOW OVEN

-

PN1809MKIII

-

ColorWHITE

-

Weight950Kg

-

Lead Time1-2days

-

ApplicationPCB SOLDER REFLOW

-

Place of OriginChina

-

Brand NameHELLER

-

CertificationCE

-

Model Number1809MKIII

-

Minimum Order Quantity1

-

Price1

-

Packaging DetailsPaperbox

-

Delivery Time1-2 work days

-

Payment TermsT/T, Western Union,paypal

-

Supply Ability100pcs/day

CNSMT Supply Heller Smt Production Line 1809MKIII 1809EXL Used Reflow Oven 9 Zone Heats 2 Cool Zone

CNSMT SUPPLY HELLER 1809MKIII 1809EXL Used reflow oven 9zone heats 2 cool zone

CNSMT SUPPLY HELLER 1809MKIII 1809EXL Used reflow oven 9zone heats 2 cool zone

keyworkds

Part name:HELLER REFLOW OVEN

MODEL: 1809MKIII 1809EXL

SMT REFLOW OVEN

SMT PCB SOLDER REFLOW

SMT FULL AUTOMATIC REFLOW OVEN

HELLER 9HEAT ZONE LARGE SIZE REFLOW OVEN

| HELLER reflow 1809EXL specifications: |

| 1.Heating zone / cooling zone: |

| Number of heating zones: upper 9 / lower 9 (both above and below the IR furnace) |

| Heating zone length: 2660mm |

| Number of cooling zones: 2 |

| 2.Input voltage: |

| 380V three-phase, 50 / 60HZ |

| 3.Specifications: |

| Dimensions: 4650mm long X1371mm wide X1600mm high |

| Weight: 1588 kg (air furnace) (nitrogen furnace weight depends on previous configuration) |

| 4.Temperature control: |

| Temperature control accuracy: ± 0.1 ℃ |

| Temperature difference across the plate: ± 2.0 ℃ |

| Temperature control range: 25-350 ℃ |

| Heating wire material: Nickel-chromium alloy coil with quick response |

| Start-up heating time: 1-5 minutes (15-20 minutes, nitrogen furnace) |

| Profile switching time: 1-15 minutes (15-20 minutes, nitrogen furnace) |

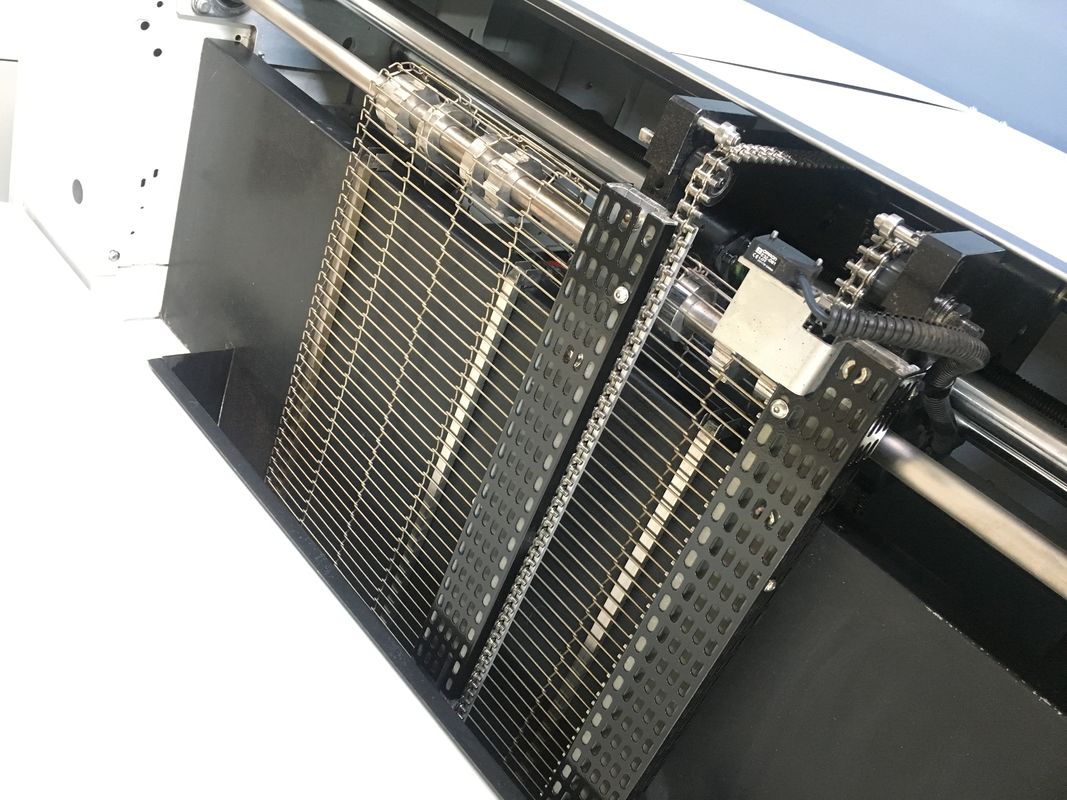

| 5.PCB board transfer system: |

| Transmission method: mesh belt transmission, chain transmission |

| Transmission speed: 250-1880mm / min |

| Rail high speed: 940mm ± 50mm |

| Mesh belt height: 890mm ± 75mm |

| Allowed board width: 50-508mm (50-380 minutes, nitrogen furnace) |

| 6.Nitrogen operation: |

| Oxygen content in the furnace: 50-1000PPM |

| Required nitrogen flow: 14-28 cubic meters per hour |

| Flux residue treatment: filter-free separation system |

| 7.Computer operating system: |

| Computer specifications: IBM Celeron 1.7GHz or more |

| Display: 15-inch CRT |

| Operating platform: Windows XP |

| HELLER1809MKIII reflow oven specifications: |

| Power input (3-phase) standard: 480 volts |

| Circuit breaker size: 100amps @ 480v |

| Kilowatt: 8.5-10.5 continuous |

| Typical operating current: 20-25amps @ 480v |

| Optional power input available: 208/240/380/400/440/415 VAC |

| Frequency: 50/60 Hz |

| Continuous Zone Open: Standard |

| Single-phase operation: Not available |

| Equipment size: L4650 × W1370 × H1600 (mm) |

| Net weight: 1588kg |

| AMD or Intel Computer: Standard |

| Recipe storage:> 500 |

| Flat-screen display: Standard |

| Windows operating system: Windows XP® |

| Large PCB width: 20 cm (50.8 cm) |

| Space required between PCBs: 0.0 cm |

| Conveyor length loading: 18 cm (46 cm) |

| Conveyor length unloading: 18 cm (46 cm) |

| Heating tunnel length: 105 cm (254 cm) |

| Process gap above mesh belt: 2.3 cm (5.8 cm) |

| Mesh belt spacing: 0.5 cm (1.27 cm) |

| Large conveying speed: 74cm / Min (188 cm / min.) |

| Conveyor direction from left to right: standard |

| Conveyor direction from right to left: optional |

| Conveyor speed control type: closed loop |

| Height from floor-standard: 37.0 cm ± 2.0 cm (94 cm ± 5 cm) |

| Floor height-optional: 32.6 cm + 3.9 cm /-. 4 cm (83 cm + 10 cm / -1 cm) |

| Clearance above the conveyor: 1.15 cm (2.9 cm) |

| Clearance under the conveyor: 1.15 cm (2.9 cm) |

| PCB support foot length: .187 cm (4.75 mm) |

| 3 mm long support pin: optional |

| Small / large board width: 2.0 cm-18 cm (5-45.7 cm) |

| Edge-holding track heater: Not required |

| Power width adjustment: standard |

| Computer-controlled width adjustment: optional |

| Automatic lubrication system: standard |

| Like: 9 |

| Base: 9 |

| Heater type: Instant response open coil |

| Heater material: nickel-chromium alloy |

| Infrared panel heater (for curing): optional |

| Temperature controller accuracy: ± .1 ° C |

| Cross-band temperature tolerance: ± 3.0 ° C |

| Heater power per zone: 6000 watts |

| Temperature range standard: 25-350 ° C |

| High temperature up to 400 ° C: optional |

| High temperature up to 450 ° C: optional |

| Insulation type: Calcium Silicate |

| UV curing: optional |

| Number of cooling zones: 2- (3 optional) |

| Extra cooling area (external): optional |

![]()

Contact:

CNSMT Electronics Equipment Co,.LTD

Ms:Lizzy wong

Email:Lizzy@smtlinemachine.com

info@smtlinemachine.com

www.smtlinemachine.com

Mb/whatsapp/wechat:+8615915451009

SKYPE:smtdwx