RY-K388: Automatic Double-Head Pressure and Insertion Shell Waterproof Bolt Machine

-

Highlight

automatic double-head bolt machine

,waterproof insertion shell machine

,SMT line pressure bolt machine

-

Brand NameAutomatic Double-Head Pressure and insertion Shell Waterproof Bolt Machine

-

Model NumberRY-K388

-

Minimum Order Quantity1 set of machine or mixed order is also acceptable Transport: By Bulk or Containers

-

PriceNegotiable

-

Packaging DetailsStandard export boxes and sturdy hardwood packages are both options

-

Delivery Time5-8 Working days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union,MoneyGram

RY-K388: Automatic Double-Head Pressure and Insertion Shell Waterproof Bolt Machine

The RY-K388 Automatic Double-Head Pressure and Insertion Shell Waterproof Bolt Machine is engineered for efficient wire processing, specifically designed to automate cutting, stripping, crimping, and threading waterproof bolts. It also handles threading rubber shells and performs essential testing. This machine streamlines the creation of wire harnesses with waterproof connections, ensuring consistent quality and high output in manufacturing environments.

The RY-K388 is essential for industries requiring dependable waterproof connections in their products. Typical applications span automotive wiring, electronics assembly, and appliance production, where sealing against environmental factors is crucial. It significantly boosts productivity by automating multiple steps in the wire termination process.

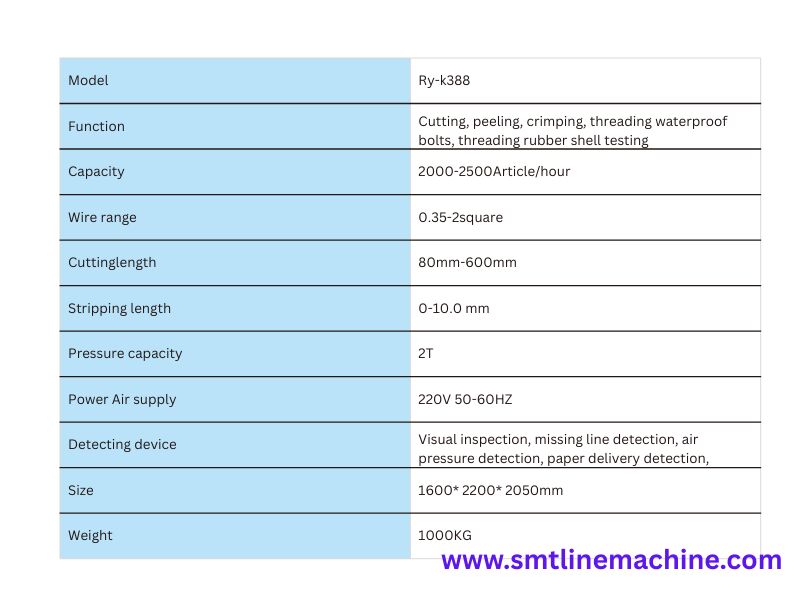

| Model | RY-K388 |

|---|---|

| Function | Cutting, peeling, crimping, threading waterproof bolts, threading rubber shell testing |

| Capacity | 2000-2500 Articles/hour |

| Wire Range | 0.35-2 square |

| Cutting Length | 80mm-600mm |

| Stripping Length | 0-10.0 mm |

| Pressure Capacity | 2T |

| Power Air Supply | 220V 50-60HZ |

| Detecting Device | Visual inspection, missing line detection, air pressure detection, paper delivery detection, pressure detection |

| Size | 1600 × 2200 × 2050mm |

| Weight | 1000KG |

- Wire Feeding and Cutting: The machine automatically feeds wires from a spool and cuts them to the specified length (80mm to 600mm).

- Stripping: Wire ends are stripped of insulation with precise length control (adjustable up to 10.0 mm).

- Terminal Crimping: Terminals are automatically attached using a pressure system for secure electrical connections.

- Waterproof Bolt and Shell Insertion: Double-head design allows simultaneous processing of both wire ends for waterproof bolt and rubber shell insertion.

- Threading: Waterproof bolts are threaded and tightened to ensure proper waterproof sealing.

- Quality Control and Detection: Multiple detection systems monitor visual defects, missing components, air pressure, material feeding, and pressure application.

- Testing: Additional testing ensures waterproof seal integrity and electrical connection quality.

- Output and Collection: Completed wire harnesses are automatically output and collected for further processing.

- Double-Head Design: Processes both ends of a wire simultaneously for maximum throughput

- High Capacity: Processes 2000-2500 pieces per hour for high-volume demands

- Wire Range Flexibility: Handles wires from 0.35 to 2 square millimeters

- Comprehensive Detection System: Includes visual inspection, missing line detection, air pressure monitoring, paper delivery verification, and pressure sensing

- Multi-Functional: Integrates cutting, stripping, crimping, and threading into a single automated process

- Enhanced Production Speed: Automates multiple processes to significantly increase production rates

- Consistent Connection Quality: Ensures reliable and uniform connections, reducing defects

- Reduced Labor Costs: Automation decreases manual labor requirements, lowering operational expenses

- Streamlined Production: Combines several functions into one machine, simplifying manufacturing processes

- Improved Quality Control: Detection systems minimize errors and maintain high-quality output

The RY-K388 Automatic Double-Head Pressure and Insertion Shell Waterproof Bolt Machine is a key tool for manufacturers needing to produce numerous waterproof wire connections. Its comprehensive features and automation capabilities offer a cost-effective solution to boost production speed and improve quality.

Phone: +8613537875415

Email: Lizzy@smtlinemachine.com

Address: Xintian Industrial Area, Baoan, Shenzhen City, China

- Delivery: 5-8 business days (varies based on order quantity)

- Minimum Order: Single machine or mixed orders accepted

- Transportation: Bulk shipping or container transport based on order size

- Payment Terms: L/C, D/A, D/P, T/T, Western Union, MoneyGram

- Price: Negotiable for optimal value

- Packaging: Standard export boxes or robust hardwood packages for secure delivery