SA-ST920 Full Automatic Wire Cutting, Stripping, Copper Belt Splicing Machine

-

Highlight

automatic wire cutting stripping machine

,copper belt splicing machine

,SMT line wire processing machine

-

Place of OriginCHINA

-

Brand NameFull Automatic Wire Cutting, Stripping, Copper Belt Splicing Machine

-

CertificationCE

-

Model NumberSA-ST920

-

Minimum Order Quantity1 set of machine or mixed order is also acceptable Transport: By Bulk or Containers

-

PriceNegotiable

-

Packaging DetailsStandard export boxes and sturdy hardwood packages are both options

-

Delivery Time5-8 Working days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union,MoneyGram

SA-ST920 Full Automatic Wire Cutting, Stripping, Copper Belt Splicing Machine

SA-ST920 Full Automatic Wire Cutting, Stripping, Copper Belt Splicing Machine

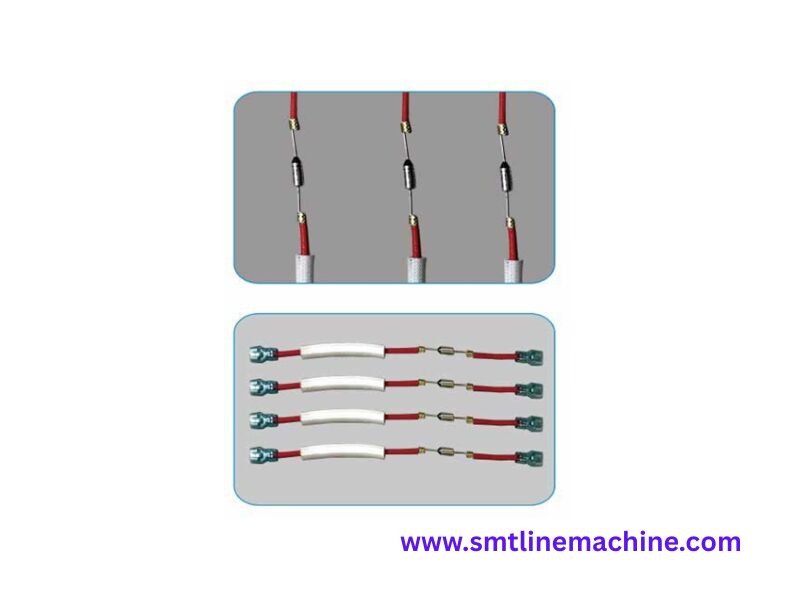

The SA-ST920 represents a significant advancement in automated wire processing technology, seamlessly integrating cutting, stripping, terminal crimping, copper belt splicing, and heat shrink tube insertion into a single, high-performance machine. This all-in-one solution is meticulously engineered to revolutionize wire harness production, drastically minimizing manual labor while significantly enhancing overall efficiency.

Technical Specifications

| Model | SA-ST920 |

|---|---|

| Function | Automatic wire cut, strip, crimping terminal, splicing copper belt wire and shrinking tube insert machine |

| Capacity | 1400-1800 Article/hour |

| Wire range | AWG#14-AWG#20 |

| Cutting length | 60mm-9999mm |

| Stripping length | 15-30mm |

| Pressure capacity | 2T |

| Power Air supply | 0.5-0.7Mpa |

| Detecting device | Knot detection, wire detection, copper strip detection, insurance detection, air pressure detection |

| Size | 1900*1200*1800mm |

| Weight | 1100KG |

Product Features

- New 4-ton copper strip machine for crimping fuses with 120N tensile strength capability

- Automated crimping and sheath insertion for 187/250 straight terminals

- Crimping and heat shrink tubing application for 187/250 straight and O-ring terminals

- Servo motor integration for precise control

- Flag terminal crimping without protective sheath requirement

Operation Process

The SA-ST920 operates through a sophisticated automated sequence. Wire is automatically fed into the system, precisely cut to predetermined lengths, and insulation is stripped with exacting accuracy. This is followed by secure terminal crimping, precise copper belt splicing, and heat shrink tube insertion for optimal insulation and protection. Servo motors ensure unparalleled control throughout each operation, while integrated detection mechanisms monitor every stage to maintain impeccable accuracy and consistent quality.

Key Advantages

- Extensive Automation: Executes multiple wire processing tasks autonomously, reducing manual interventions

- High Production Capacity: Processes 1400-1800 articles per hour for demanding deadlines

- Functional Versatility: Accommodates wire sizes from AWG#14 to AWG#20 with diverse operations

- Quality Assurance: Advanced detection systems ensure consistent quality and minimize defects

Technical Attributes

- Wire Compatibility: AWG#14 to AWG#20

- Cutting Precision: 60mm to 9999mm range

- Stripping Accuracy: 15mm to 30mm range

- Pressure Performance: 2T capacity for secure connections

- Air Supply: 0.5-0.7Mpa for optimal efficiency

- Detection Systems: Comprehensive monitoring for reliable operation

Common Applications

- Wire harness manufacturing across diverse industries

- Cable assembly operations with precise cutting and termination

- Electrical component production requiring meticulous wire processing

Advanced Technologies

- State-of-the-art servo motor integration for precise control

- Intelligent automation systems for workflow regulation

- User-friendly programmable controls for parameter adjustment

Business Benefits

- Significantly elevated productivity levels

- Reduced labor expenses and operational costs

- Enhanced product quality and reduced waste

- Superior operational reliability with minimized downtime

Product Overview

The SA-ST920 Full Automatic Wire Cutting, Stripping Copper Belt Splicing Machine is an indispensable asset for modern wire processing operations. This comprehensive solution automates intricate tasks, amplifies productivity, and elevates overall quality. With advanced features and unparalleled functional versatility, this machine represents a valuable investment for businesses in wire harness and cable assembly sectors.

Contact Information:

Phone: +8613537875415

Email: Lizzy@smtlinemachine.com

Address: Xintian Industrial Area, Baoan, Shenzhen City, China

Packaging and Delivery

- Delivery: 5-8 business days (varies by order quantity)

- Minimum Order: Single machine or mixed orders accepted

- Transportation: Bulk or container shipping based on order size

- Payment Terms: L/C, D/A, D/P, T/T, Western Union, MoneyGram

- Price: Negotiable for optimal value

- Packaging: Standard export boxes or robust hardwood packages