-

Highlight

fully automatic crimping machine

,2-wire three-end crimper

,SMT line crimping machine

-

Place of OriginCHINA

-

Brand NameFully Automatic 2-Wire Three-End Crimping Machine

-

CertificationCE

-

Model NumberSA-1600-3

-

Minimum Order Quantity1 set of machine or mixed order is also acceptable Transport: By Bulk or Containers

-

PriceNegotiable

-

Packaging DetailsStandard export boxes and sturdy hardwood packages are both options

-

Delivery Time5-8 Working days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union,MoneyGram

SA-1600-3 Fully Automatic 2-Wire Three-End Crimping Machine

SA-1600-3 Fully Automatic 2-Wire Three-End Crimping Machine

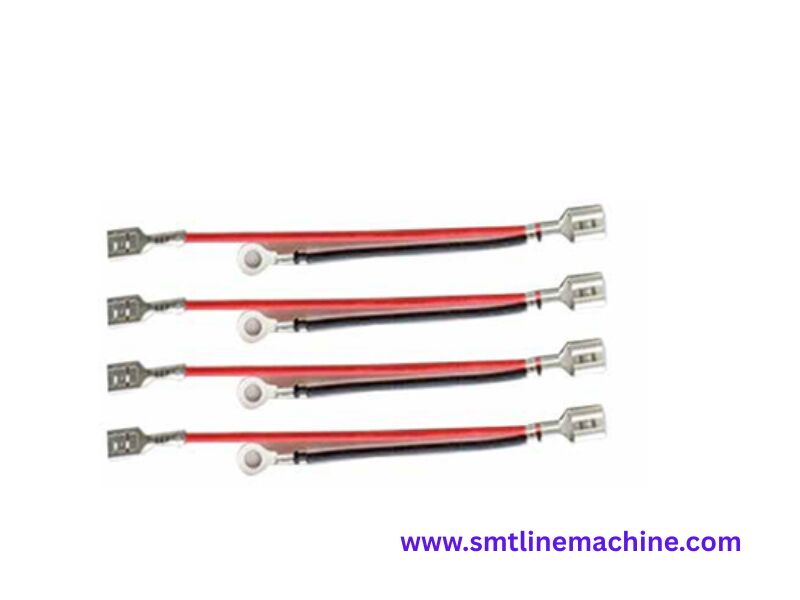

The SA-1600-3 Fully Automatic 2-Wire Three-End Crimping Machine is designed for efficient wire harness production. This advanced machine automates the complex tasks of cutting, stripping, and crimping wires, significantly reducing manual labor requirements while increasing production output, improving quality, and lowering operational costs.

Technical Specifications

| Model | SA-1600-3 |

|---|---|

| Function | Automatic 2 wire cutting stripping and joint two wire together with 3 terminal crimping machine |

| Capacity | Three end crimping: ~2000 pieces/hour Double wire and punching: ~3000 pieces/hour Double end crimping: ~3200 pieces/hour Single end crimping: ~4500 pieces/hour |

| Wire range | AWG#14-AWG#28 |

| Cutting length | 20mm-9999mm |

| Stripping length | 0-10mm |

| Pressure capacity | 2-3T |

| Power Air supply | 220V 50-60HZ 0.5-0.7Mpa |

| Detecting device | Wire knot detection, wire presence detection, terminal crimping detection, air pressure detection |

| Size | 1700*850*1800mm |

| Weight | 680KG |

Product Features

-

Automatic Wire HandlingAutomatically cuts, strips, and connects two wires while adding three terminals for secure connections

-

High-Speed ProductionThree-end crimping: Up to 2000 pieces/hour

Double wire and punching: Up to 3000 pieces/hour

Double-end crimping: Up to 3200 pieces/hour

Single-end crimping: Up to 4500 pieces/hour -

Versatile Wire CompatibilityHandles wire sizes from AWG#14 to AWG#28 for various applications

-

Adjustable SettingsCutting length: 20mm to 9999mm

Stripping length: 0 to 10mm -

Strong Crimping Performance2-3T pressure capacity ensures secure terminal connections

-

Comprehensive Detection SystemsWire knot detection, wire presence detection, terminal crimping detection, and air pressure monitoring

-

Easy OperationPower: 220V, 50-60Hz

Air supply: 0.5-0.7Mpa -

Compact Design1700mm x 850mm x 1800mm dimensions fit most factory layouts

-

Durable Construction680KG weight ensures robust, long-term performance

Applications

- Automotive Manufacturing: Wire sets for vehicles

- Electronics: Cables for electronic devices

- Home Appliances: Wiring for refrigerators, washing machines, and other appliances

- Communication: Cables for phones and internet equipment

- Factory Automation: Machine wiring in industrial facilities

- Aerospace: Reliable wire sets for aircraft

- Renewable Energy: Wiring for solar panels and wind turbines

Key Advantages

- Increased Production: Faster output helps meet tight deadlines

- Superior Quality: Reduces errors and ensures proper wire connections

- Cost Savings: Reduced manual labor lowers operational costs

- Enhanced Safety: Automates hazardous tasks to minimize injury risks

- Flexibility: Compatible with various wire sizes and types

- Efficiency: Optimizes material and energy usage to reduce waste

Operation Process

- Wire Feeding: Two wires are automatically fed into the machine

- Cutting: Wires are cut to the specified length

- Stripping: Insulation is removed from wire ends

- Terminal Attachment: Wires are connected and three terminals are crimped onto the ends

- Quality Check: Automated verification ensures proper completion

- Output: Completed wire sets are automatically collected

Product Overview

The SA-1600-3 Fully Automatic 2-Wire Three-End Crimping Machine represents a significant advancement in wire harness manufacturing technology. This system streamlines production processes, delivering faster output with enhanced reliability. With its robust construction and versatile applications, it represents an excellent investment for companies seeking to optimize their wire production capabilities.

Packaging and Delivery Information

- Delivery: 5-8 business days (varies based on order quantity)

- Minimum Order: Single machine or mixed orders accepted

- Transportation: Bulk shipping or container options available

- Payment Terms: L/C, D/A, D/P, T/T, Western Union, MoneyGram

- Price: Negotiable for optimal value

- Packaging: Standard export boxes or robust hardwood packages

Contact Information:

Phone: +8613537875415

Email: Lizzy@smtlinemachine.com

Address: Xintian Industrial Area, Baoan, Shenzhen City, China

Phone: +8613537875415

Email: Lizzy@smtlinemachine.com

Address: Xintian Industrial Area, Baoan, Shenzhen City, China