SA-8050B Fully automatic double head crimping heat shrink tubing machine

-

Highlight

fully automatic heat shrink tubing machine

,double head crimping machine

,SMT line crimping machine with warranty

-

Place of OriginCHINA

-

Brand NameFully automatic double head crimping heat shrink tubing machine

-

CertificationCE

-

Model NumberSA-8050B

-

Minimum Order Quantity1 set of machine or mixed order is also acceptable Transport: By Bulk or Containers

-

PriceNegotiable

-

Packaging DetailsStandard export boxes and sturdy hardwood packages are both options

-

Delivery Time5-8 Working days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union,MoneyGram

SA-8050B Fully automatic double head crimping heat shrink tubing machine

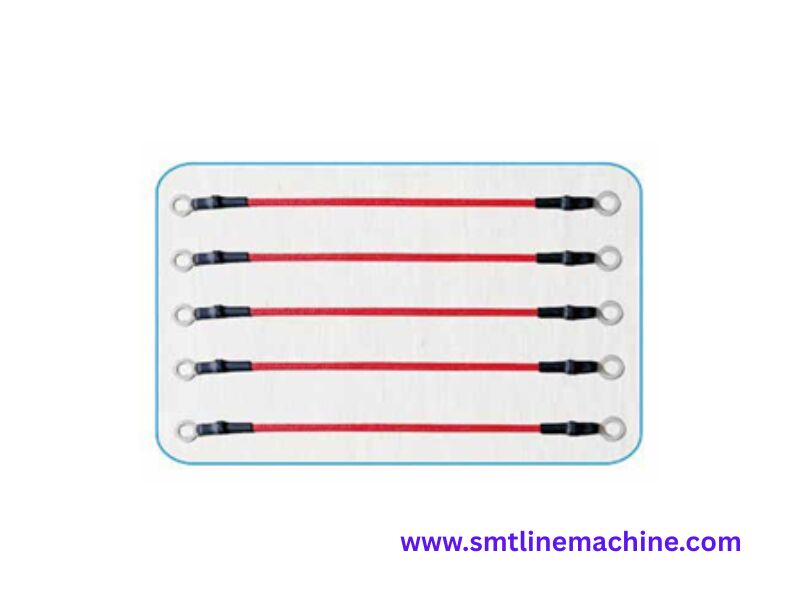

The SA-8050B is a fully automatic, double-head crimping and heat shrink tubing machine designed for high-precision wire processing. It integrates cutting, stripping, threading, terminal crimping, and heat shrinking into a single, efficient operation. This machine maximizes productivity while ensuring consistent quality, making it an ideal solution for businesses looking to streamline their wiring processes.

| Model | SA-8050B |

|---|---|

| Function | Automatic double end crimping, shrink tube heating machine |

| Capacity | 1800-2300 Article/hour |

| Wire range | AWG#24-AWG#8 |

| Cutting length | 300mm-9999mm |

| Stripping length | 1-15mm |

| Heat shrink tubing length | 15mm-35mm |

| Pressure capacity | 2T |

| Power Air supply | 220V 50-60HZ 0.5-0.7Mpa |

| Detecting device | Wire knot detection, wire presence detection, terminal crimping detection, air pressure detection |

| Size | 2000*850*1800mm |

| Weight | about 750KG |

- Premium-Grade Components: Built with high-end, high-precision components from reputable manufacturers for durability and consistent performance.

- Intuitive User Interface: User-friendly touch screen interface powered by icon-based KINCO software for easy operation and monitoring.

- Integrated Functionality: Performs complete wire processing tasks in a single automated cycle, eliminating the need for multiple machines.

- Advanced Servo Control System: Ensures precise and repeatable motion control for high-speed operation and exceptional product quality.

- Versatile Wire Size Compatibility: Accommodates wire sizes from AWG#24 to AWG#8 for various applications.

- Adjustable Length Parameters: Supports cutting lengths from 300mm to 9999mm, stripping lengths from 1-15mm, and heat shrink tubing lengths from 15mm to 35mm.

- Comprehensive Detection System: Monitors for wire knots, wire presence, proper terminal crimping, and air pressure to ensure consistent quality.

- Enhanced Operational Efficiency: Automates multiple wire processing tasks to reduce production time and labor costs.

- High Production Throughput: Processes 1800-2300 articles per hour to meet demanding production schedules.

- Reduced Labor Dependency: Minimizes manual labor requirements, freeing employees for other critical tasks.

- Consistent Product Quality: Combines servo control and detection systems to maintain high quality standards.

- Adaptability to Diverse Applications: Suitable for various industries and projects, maximizing return on investment.

- Simplified Operation and Maintenance: Intuitive interface and robust design reduce training needs and downtime.

- Automotive Wiring Harnesses: Manufacturing complex wiring harnesses for vehicles

- Consumer Electronics: Producing wire assemblies for televisions, computers, and mobile devices

- Appliance Manufacturing: Creating wiring for household appliances

- Telecommunications Equipment: Assembling cables and wiring for routers, switches, and modems

- Industrial Control Systems: Wiring control panels for industrial machinery and automation

- Aerospace Industry: Manufacturing high-reliability wiring harnesses for aircraft

- Medical Devices: Producing wire assemblies for diagnostic and monitoring equipment

- Automated Wire Feeding: Wires are automatically fed from a spool or feeder system

- Precision Cutting and Stripping: Wires are cut to specified length and insulation is stripped from ends

- Automated Threading Process: Stripped wire ends are threaded through heat shrink tubing

- High-Force Terminal Crimping: Terminals are crimped onto wire ends for secure electrical connection

- Controlled Heat Shrinking: Tubing is heated to shrink tightly around wire and terminal

- Real-Time Detection and Monitoring: Continuous monitoring ensures quality and stops machine if issues detected

- Automated Output and Collection: Finished assemblies are ejected and collected automatically

The SA-8050B Automatic Double Head Crimping Heat Shrink Tubing Machine is a cutting-edge solution that offers unparalleled efficiency, quality, and versatility for wire processing applications. Its advanced features, robust design, and user-friendly interface make it an ideal investment for businesses looking to streamline operations, reduce costs, and improve product quality.

Contact Information:

Phone: +8613537875415

Email: Lizzy@smtlinemachine.com

Address: Xintian Industrial Area, Baoan, Shenzhen City, China

Delivery: 5-8 business days (varies based on quantity ordered)

Minimum Order: Single machine or mixed orders accepted

Transportation: Bulk or container shipping based on order size

Payment Terms: L/C, D/A, D/P, T/T, Western Union, MoneyGram

Price: Negotiable for best value

Packaging: Standard export boxes or robust hardwood packages