-

Highlight

auto single-end crimp machine

,twist and tin insertion machine

,SMT line crimp housing machine

-

Brand NameAuto Single-End Crimp, Twist, Tin & Housing Insertion Machine

-

Model NumberRY-07S

-

Minimum Order Quantity1 set of machine or mixed order is also acceptable Transport: By Bulk or Containers

-

PriceNegotiable

-

Packaging DetailsStandard export boxes and sturdy hardwood packages are both options

-

Delivery Time5-8 Working days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union,MoneyGram

RY-07S Auto Single-End Crimp, Twist, Tin & Housing Insertion Machine

The RY-07S Auto Single-End Crimp, Twist, Tin & Housing Insertion Machine is used in many industries to make wire work easier. It helps build wire systems for cars, create cables for electronics like phones and computers, and make the wiring for appliances in your home. It's also used to put together wires for phone and internet equipment. Basically, it's great for any job that needs lots of wires done quickly and correctly.

The RY-07S Auto Single-End Crimp, Twist, Tin & Housing Insertion Machine is a fully automated machine meticulously engineered to revolutionize wire processing. By integrating a suite of functions into a single, cohesive unit, the RY-07S significantly streamlines the production of wire harnesses and cable assemblies.

This advanced system is an indispensable asset for manufacturers aiming to elevate productivity, diminish labor expenses, and uphold unparalleled consistency in product quality. It represents a forward-thinking solution for modern manufacturing challenges.

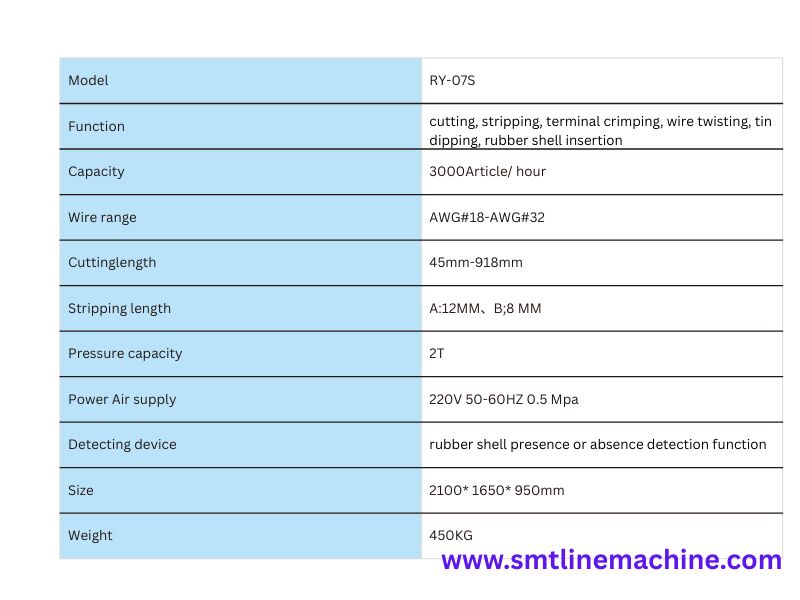

| Model | RY-07S |

|---|---|

| Function | cutting, stripping, terminal crimping, wire twisting, tin dipping, rubber shell insertion |

| Capacity | 3000 Article/hour |

| Wire range | AWG#18-AWG#32 |

| Cutting length | 45mm-918mm |

| Stripping length | A:12MM, B:8 MM |

| Pressure capacity | 2T |

| Power Air supply | 220V 50-60HZ 0.5 Mpa |

| Detecting device | rubber shell presence or absence detection function |

| Size | 2100*1650*950mm |

| Weight | 450KG |

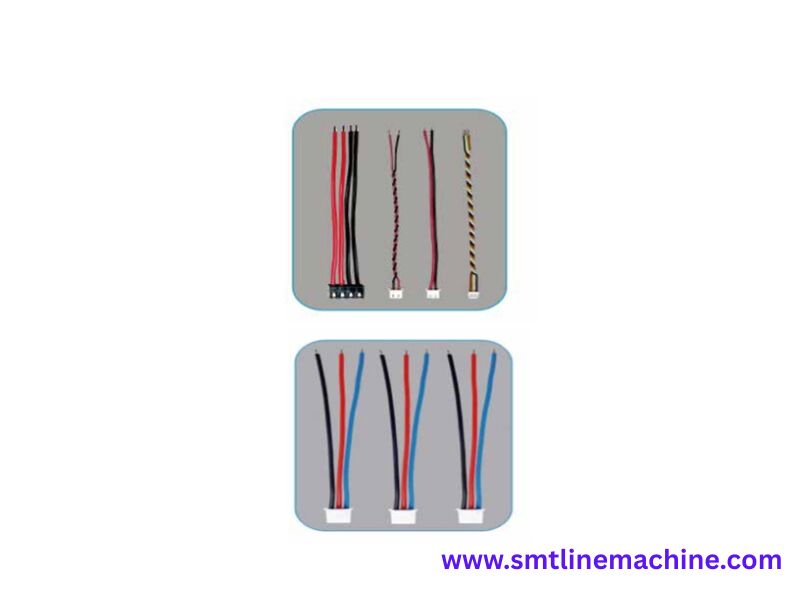

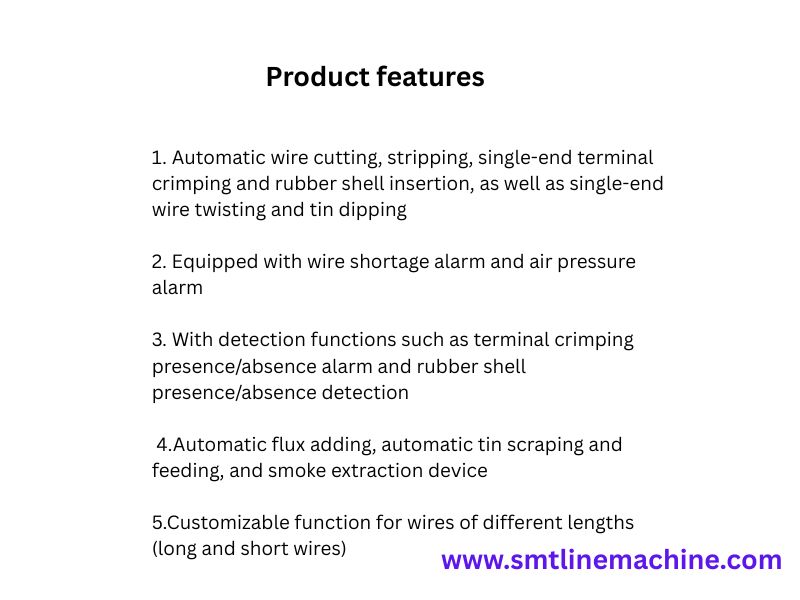

- Comprehensive All-in-One Automation: The RY-07S expertly manages automatic wire cutting, precise stripping, secure single-end terminal crimping, reliable rubber shell insertion, meticulous single-end wire twisting, and protective tin dipping. This comprehensive automation reduces the need for multiple machines and manual intervention.

- Exceptional High Capacity: With an impressive capacity of 3000 articles per hour, the RY-07S dramatically enhances production throughput, enabling manufacturers to meet demanding deadlines and scale operations efficiently.

- Broad Versatile Wire Range: Accommodating a wire range from AWG#18 to AWG#32, this machine offers unparalleled versatility. It's perfectly suited for a wide array of applications, ensuring compatibility with various wire types and sizes.

- Precision Cutting Capabilities: Offering a cutting length range from 45mm to 918mm, the RY-07S provides exceptional flexibility for producing wires of different lengths, catering to diverse project requirements with utmost accuracy.

- Advanced Adjustable Stripping Length: Featuring stripping lengths of A:12mm and B:8mm, the machine ensures precise and clean wire preparation. This feature is crucial for achieving optimal electrical connections and preventing potential short circuits.

- Sophisticated Advanced Detection Systems: Equipped with a suite of detection mechanisms, including wire shortage alarms, air pressure alerts, terminal crimping presence/absence detection, and rubber shell presence/absence detection. The RY-07S minimizes errors and reduces downtime, ensuring continuous and reliable operation.

- Enhanced Safety Protocols: Incorporating automatic flux adding, automatic tin scraping and feeding, and a highly efficient smoke extraction device, the RY-07S maintains a safe, clean, and healthy working environment. These features protect operators from harmful fumes and ensure compliance with stringent safety standards.

- Customizable Functionality Options: Offering customizable functions for processing wires of varying lengths, the RY-07S can be tailored to meet specific production needs. This adaptability ensures that the machine seamlessly integrates into existing workflows and accommodates unique project demands.

- Revolutionizing the Automotive Industry: Essential for manufacturing complex wire harnesses that power modern vehicles, ensuring reliability and safety.

- Advancing Electronics Manufacturing: Plays a crucial role in producing intricate cable assemblies for a wide range of electronic devices, from smartphones to sophisticated computer systems.

- Elevating Appliance Manufacturing: Used in creating precise wiring for household appliances, ensuring efficient and safe operation of everyday devices.

- Optimizing Telecommunications Infrastructure: Vital for assembling wires used in communication equipment, supporting seamless connectivity and data transmission.

- Automated Wire Cutting and Stripping: The RY-07S automatically cuts wires to the precise length required and strips the insulation from one end with unparalleled accuracy.

- Precision Terminal Crimping: A terminal is automatically and securely crimped onto the stripped end of the wire, ensuring a robust and reliable electrical connection that meets stringent industry standards.

- Reliable Rubber Shell Insertion: The machine expertly inserts the crimped wire into a rubber shell, providing essential insulation and protection against environmental factors, thereby extending the lifespan of the connection.

- Enhanced Wire Twisting and Tin Dipping: The wire end is twisted to maximize conductivity and then meticulously dipped in molten tin to prevent corrosion and significantly enhance solderability, ensuring long-term performance.

- Stringent Quality Control Measures: Throughout the entire process, the machine's advanced detection system vigilantly monitors for wire shortages, air pressure anomalies, and the presence/absence of terminals and rubber shells, guaranteeing consistently high-quality output and minimizing potential defects.

The RY-07S Auto Single-End Crimp, Twist, Tin & Housing Insertion Machine represents a transformative advancement in wire processing technology. Its comprehensive automation, high capacity, and sophisticated detection features make it an invaluable asset for any manufacturing operation seeking to enhance efficiency, improve quality, and reduce operational costs. Investing in the RY-07S is a strategic move that will undoubtedly elevate your production capabilities and ensure a competitive edge in today's dynamic market.

For inquiries, please contact us at:

Phone: +8613537875415

Email: Lizzy@smtlinemachine.com

Address: Xintian Industrial Area, Baoan, Shenzhen City, China

Delivery: Expect your order to arrive within 5-8 business days, though this timeframe can vary based on the quantity ordered.

Minimum Order: We accept orders for a single machine or mixed orders to suit your needs.

Transportation: Products are shipped either in bulk or via containers, depending on the order size and destination.

Payment Terms: Flexible payment options are available, including L/C, D/A, D/P, T/T, Western Union, and MoneyGram.

Price: Prices are negotiable to ensure you receive the best possible value.

Packaging: We offer both standard export boxes and robust hardwood packages to ensure your order arrives safely and securely.