-

Highlight

automated wire processing machine

,SMT line machine with housing loading

,tin dipping wire processing equipment

-

Brand NameAutomated Wire Processing with Housing Loading & Tin Dipping

-

Model NumberRY-K288

-

Minimum Order Quantity1 set of machine or mixed order is also acceptable Transport: By Bulk or Containers

-

PriceNegotiable

-

Packaging DetailsStandard export boxes and sturdy hardwood packages are both options

-

Delivery Time5-8 Working days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union,MoneyGram

RY-K288: Automated Wire Processing with Housing Loading & Tin Dipping

RY-K288: Automated Wire Processing with Housing Loading & Tin Dipping

The RY-K288 is an automated machine that combines terminal crimping, waterproof plug insertion, housing loading, and tin dipping into one system. This all-in-one machine simplifies wire processing by automatically cutting, stripping, crimping, and soldering wires. It uses a vibrating disk feeding system to load housings efficiently and can handle different wire lengths and configurations.

This RY-K288: Automated Wire Processing with Housing Loading & Tin Dipping machine helps manufacturers increase productivity and maintain high-quality standards. It includes optional features like pull force testing and terminal height inspection to ensure reliable connections. With a magnifier and data storage, the RY-K288 offers full traceability for quality control. Its detection systems minimize errors and reduce waste.

How It Works

The RY-K288 automates wire processing through a series of integrated steps. Initially, the machine takes spooled wire and precisely cuts it to the designated length. Following this, the ends of the wire are stripped, exposing the conductive core and preparing them for subsequent operations. The automatic housing loading system, utilizing a vibrating disk feeder, then loads the appropriate housings onto the wires, ensuring accurate placement and a steady supply.

Next, the exposed wire ends undergo terminal crimping, creating secure electrical connections that are closely monitored to meet stringent quality standards. If necessary, the machine inserts waterproof plugs to provide environmental protection for the connection.

To enhance conductivity and prevent corrosion, the wire ends are then dipped in molten tin, ensuring a reliable and long-lasting connection. Throughout the entire process, various detection systems continuously monitor wire presence, perform CCD detection, check terminal crimping, and verify housing presence. Optional pull force testing and terminal height inspection tools are also available to ensure quality further.

Finally, the machine stores data for each processed wire, enabling comprehensive traceability and quality assurance.

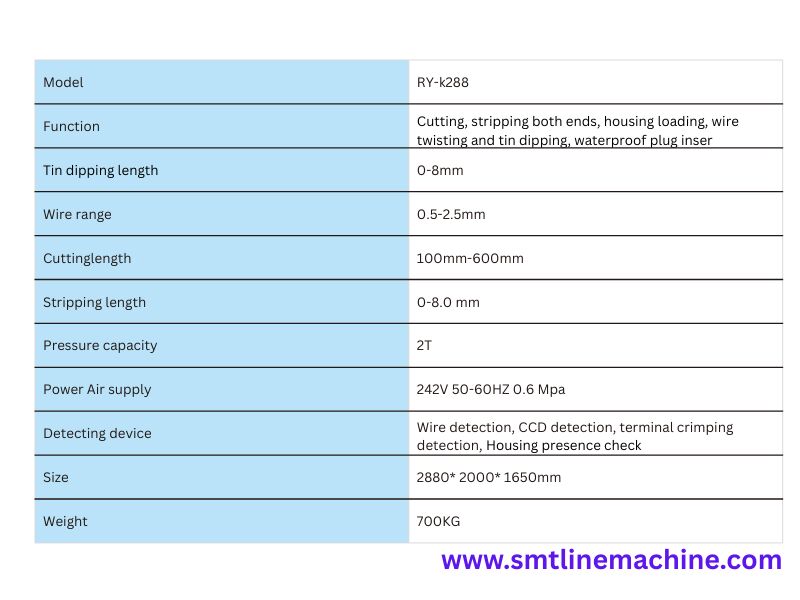

RY-K288: Automated Wire Processing with Housing Loading & Tin Dipping Specifications:

| Model | RY-k288 |

| Function | Cutting, stripping both ends, housing loading, wire twisting and tin dipping, waterproof plug inser |

| Tin dipping length | 0-8mm |

| Wire range | 0.5-2.5mm |

| Cuttinglength | 100mm-600mm |

| Stripping length | 0-8.0 mm |

| Pressure capacity | 2T |

| Power Air supply | 242V 50-60HZ 0.6 Mpa |

| Detecting device | Wire detection, CCD detection, terminal crimping detection, Housing presence check |

| Size | 2880* 2000* 1650mm |

| Weight | 700KG |

Uses and Advantages

Uses:

- Automated Wire Processing: Automates cutting, stripping, crimping, and tin dipping

- Waterproof Connector Assembly: Inserts waterproof plugs for environmental protection

- Housing Loading: Loads housings onto wires efficiently

- Quality Control: Ensures high-quality connections with optional testing

- Data Traceability: Stores data for quality assurance

Advantages:

- Increased Efficiency: Reduces production time and labor costs

- High Precision: Ensures accurate and consistent results

- Versatility: Suitable for various applications with different wire ranges and cutting lengths

- Quality Assurance: Provides comprehensive quality control and traceability

- Reduced Errors: Minimizes defects and reduces waste

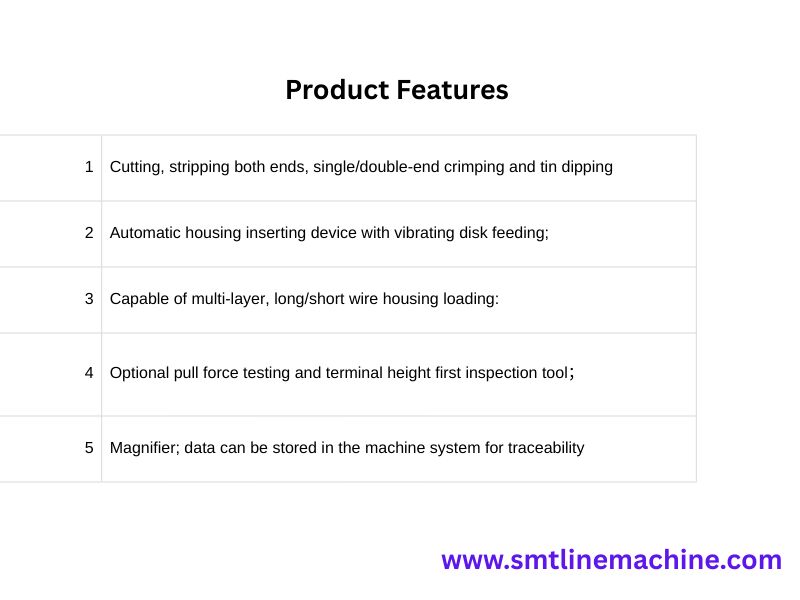

Key Features

- All-in-One Functionality: Combines multiple processes into one machine

- Automatic Housing Inserting: Uses a vibrating disk feeding system

- Multi-Layer Housing Loading: Handles different wire lengths and layers

- Optional Quality Control Tools: Includes pull force testing and terminal height inspection

- Data Traceability: Stores data for traceability

- Comprehensive Detection: Detects wire presence and checks crimping and housing

Product Overview

The RY-K288 Full-automatic Terminal Crimping, Waterproof Plug Inserting, Housing Loading and Tin Dipping All-in-one Machine is an innovative solution that enhances productivity, ensures quality, and reduces costs in wire processing. Its features and automated capabilities make it valuable for manufacturers aiming for efficiency and precision.

Contact Information:

Phone: +8613537875415

Email: Lizzy@smtlinemachine.com

Address: Xintian Industrial Area, Baoan, Shenzhen City, China

Phone: +8613537875415

Email: Lizzy@smtlinemachine.com

Address: Xintian Industrial Area, Baoan, Shenzhen City, China

Packaging and Delivery Information

Delivery: Expect your order to arrive within 5-8 business days, though this timeframe can vary based on the quantity ordered.

Minimum Order: We accept orders for a single machine or mixed orders to suit your needs.

Transportation: Products are shipped either in bulk or via containers, depending on the order size and destination.

Payment Terms: Flexible payment options are available, including L/C, D/A, D/P, T/T, Western Union, and MoneyGram.

Price: Prices are negotiable to ensure you receive the best possible value.

Packaging: We offer both standard export boxes and robust hardwood packages to ensure your order arrives safely and securely.

Minimum Order: We accept orders for a single machine or mixed orders to suit your needs.

Transportation: Products are shipped either in bulk or via containers, depending on the order size and destination.

Payment Terms: Flexible payment options are available, including L/C, D/A, D/P, T/T, Western Union, and MoneyGram.

Price: Prices are negotiable to ensure you receive the best possible value.

Packaging: We offer both standard export boxes and robust hardwood packages to ensure your order arrives safely and securely.