-

Highlight

automatic wire stripping machine with crimping

,SMT line wire stripping machine

,industrial wire crimping machine

-

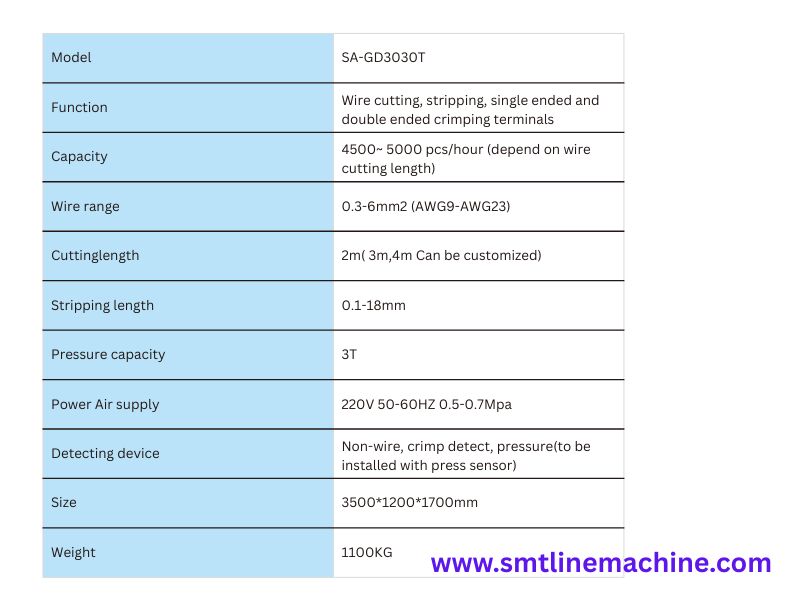

Model NumberSA-GD3030T

-

Minimum Order Quantity1 set of machine or mixed order is also acceptable Transport: By Bulk or Containers

-

PriceNegotiable

-

Packaging DetailsStandard export boxes and sturdy hardwood packages are both options

-

Delivery Time5-8 Working days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union,MoneyGram

SA-GD3030T Automatic Wire Stripping and Crimping Machine

SA-GD3030T Automatic Wire Stripping and Crimping Machine

The SA-GD3030T Automatic Wire Stripping and Crimping Machine is a cutting-edge automatic wire processing machine ideal for industries such as automotive, electronics, electrical appliances, and telecommunications. This machine is designed to handle complex wire processing tasks with ease and reliability.

Engineered to meet the demands of modern manufacturing environments, it integrates multiple wire preparation functions into a single, efficient unit, significantly improving productivity, precision, and consistency in wire harness production.

Multifunctional Capabilities

The SA-GD3030T performs a range of essential wire processing operations, including:

- Wire Cutting: Accurately cuts wires to specified length with standard options of 2 meters and extensions available for 3 and 4 meters

- Wire Stripping: Precisely removes insulation from wire ends without damaging the conductor, supporting stripping lengths from 0.1mm to 18mm

- Single-Ended Crimping: Automatically crimps terminals on one end of the wire for secure mechanical and electrical connections

- Double-Ended Crimping: Capable of crimping terminals on both ends of the wire in one continuous process

Enhanced Productivity and Efficiency

With a production capacity ranging from 4,500 to 5,000 pieces per hour (depending on wire length), the SA-GD3030T offers high-speed operation without compromising accuracy. Its robust 3-ton pressure crimping system ensures every crimp is tight and reliable, minimizing defects and rework.

Broad Wire Compatibility

This machine supports a wide wire size range, from 0.3mm² up to 6mm² (AWG 23 to AWG 9), making it versatile enough for various applications. Whether working with thin wires for delicate electronics or thicker cables for power transmission, the SA-GD3030T adapts seamlessly.

Intelligent Quality Control Features

The SA-GD3030T is equipped with advanced detection systems to maintain high-quality standards:

- Non-Wire Detection: Prevents operation if no wire is present, reducing errors and material waste

- Crimp Detection: Monitors the crimping process to identify incomplete or faulty crimps

- Pressure Sensor (Optional): Measures crimping force in real-time, providing additional quality assurance

Customizable and Expandable Options

To tailor the machine to specific production workflows, several optional features can be integrated:

- Wire Feeder: Automates wire feeding for continuous operation

- Seal Inserting Station: Inserts protective seals onto wires

- Marking Device: Applies labels or markings for identification and traceability

- Crimping Force Monitoring System: Provides detailed feedback on crimping forces

Why Choose the SA-GD3030T?

By consolidating wire cutting, stripping, and crimping into one automated process, the SA-GD3030T minimizes manual labor, reduces errors, and accelerates production cycles. Its modular design and optional upgrades allow manufacturers to customize the machine according to evolving production needs, ensuring long-term value and adaptability.

Whether producing complex wire harnesses for automotive electronics or preparing cables for industrial machinery, the SA-GD3030T delivers consistent, high-quality results with remarkable speed and precision.

Contact Information:

Phone: +8613537875415

Email: Lizzy@smtlinemachine.com

Address: Xintian Industrial Area, Baoan, Shenzhen City, China

Packaging and Delivery Information

Delivery: 5-8 business days (varies based on quantity ordered)

Minimum Order: Single machine or mixed orders accepted

Transportation: Bulk shipping or container shipping based on order size

Payment Terms: L/C, D/A, D/P, T/T, Western Union, MoneyGram

Price: Negotiable

Packaging: Standard export boxes or robust hardwood packages