-

Highlight

vacuum reflow soldering machine

,SMT reflow soldering equipment

,vacuum soldering system for SMT

-

Minimum Order Quantity1 set of machine or mixed order is also acceptable

-

PriceNegotiable

-

Packaging DetailsStandard export boxes and sturdy hardwood packages are both options

-

Delivery Time5-8 Working days

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

Vacuum reflow soldering

Vacuum Reflow Soldering

The Vacuum Reflow Soldering machine is a high-tech oven designed for soldering electronic components onto circuit boards with exceptional precision and reliability. Available in different models like the KTZ-8N and KTZ-10N, it uses a controlled heating and cooling process, sometimes with nitrogen, to create strong, void-free solder joints. This machine is ideal for industries requiring high-quality soldering, such as military, aerospace, automotive, and LED manufacturing. It features a user-friendly control system, adjustable conveyor, and an optional vacuum chamber to further reduce defects. With its ability to handle various board sizes and component heights, this soldering oven ensures consistent and dependable results for a wide range of electronic products.

Technical Specifications

| Parameter | KTZ-8N | KTZ-10N |

|---|---|---|

| Dimensions (L x W x H) | L6400 x W1695 x H1650 mm | L7170 x W1695 x H1650 mm |

| Weight | 3000 kg | 3500 kg |

| Color | Computer Grey | Computer Grey |

| Heating Zones | 8 Zones (Top) / 8 Zones (Bottom) | 10 Zones (Top) / 10 Zones (Bottom) |

| Heating Zone Length | 3110 mm | 3892 mm |

| Cooling Zones | 3 Zones (Top) / 3 Zones (Bottom) | 3 Zones (Top) / 3 Zones (Bottom) |

| Rectifying Plate Structure | Small Circulation | Small Circulation |

| Exhaust Volume Requirement | 11 m³/min x 2 (per channel) | 12 m³/min x 2 (per channel) |

| Power Supply | 3-Phase, 380V, 50/60 Hz (Optional: 220V) | 3-Phase, 380V, 50/60 Hz (Optional: 220V) |

| Total Power | 67 kW | 83 kW |

| Startup Power | 32 kW | 38 kW |

| Normal Power Consumption | 10 kW | 11 kW |

| Warm-Up Time (Approx.) | 20-25 minutes | 20-25 minutes |

| Temperature Range | Ambient to 300°C | Ambient to 300°C |

| Temperature Control | PID Closed-Loop + SSR Driving (PC + PLC) | PID Closed-Loop + SSR Driving (PC + PLC) |

| Temperature Accuracy | ±1°C | ±1°C |

| PCB Temperature Deviation | ±1°C | ±1°C |

| Data Storage | Configurable Production Parameters & Status | Configurable Production Parameters & Status |

| Alarm System | Temperature Anomaly, Board Drop | Temperature Anomaly, Board Drop |

| Alarm Indication | Tri-Color Indicator (Yellow, Green, Red) | Tri-Color Indicator (Yellow, Green, Red) |

| Rail Structure | Three Independent Rails | Three Independent Rails |

| Chain Mechanism | Anti-Jamming Single Chain Buckle | Anti-Jamming Single Chain Buckle |

| Maximum PCB Width | 150mm x 150mm; 400mm x 400mm | 150mm x 150mm; 400mm x 400mm |

| Rail Width Adjustment | 50-400 mm | 50-400 mm |

| Component Height (Max) | 30 mm (Top), 30 mm (Bottom) | 30 mm (Top), 30 mm (Bottom) |

| Conveyor Direction | Left-to-Right (Optional: Right-to-Left) | Left-to-Right (Optional: Right-to-Left) |

| Rail Fixation | Front Rail Fixed | Front Rail Fixed |

| PCB Transport | Rail + Chain Conveyor | Rail + Chain Conveyor |

| Conveyor Height | 900 ± 20 mm | 900 ± 20 mm |

| Conveyor Speed | 300-2000 mm/min | 300-2000 mm/min |

| Lubrication | Automated High-Temperature Lubricant System | Automated High-Temperature Lubricant System |

| Width Adjustment | Synchronized Three-Sectional Adjustment | Synchronized Three-Sectional Adjustment |

| Conveyor System | Independent Conveyor | Independent Conveyor |

| Ultimate Vacuum Pressure | 10 Pa | 10 Pa |

| Vacuum Extraction | Four Independent Stages | Four Independent Stages |

| Cooling Method | Forced Air | Water Chiller |

| Nitrogen System (Optional) | Enclosed System with Flow Meter & Chiller | Enclosed System with Flow Meter & Chiller |

| Nitrogen Consumption | 300-1000 ppm (with 400mm Conveyor) | 300-1000 ppm (with 400mm Conveyor) |

| Anti-Stuck Feature | Automatic PCB Thickness Adaption | Automatic PCB Thickness Adaption |

Soldering Performance Metrics

| Metric | Specification |

|---|---|

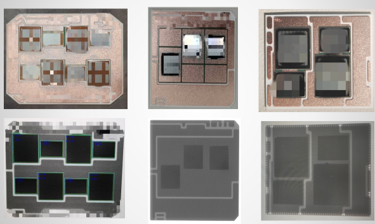

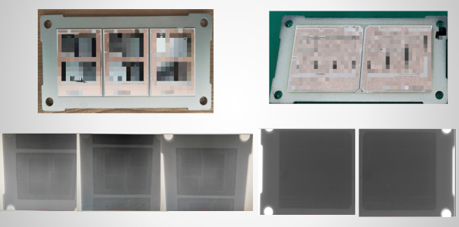

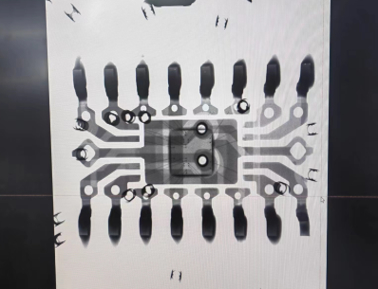

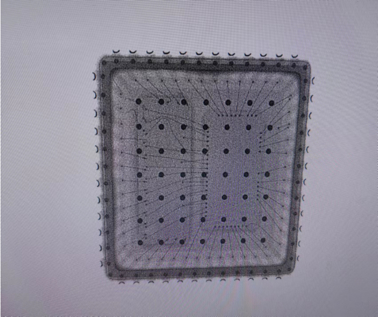

| High-Power Component Void Rate | Single Void Rate < 1%, Total Void Rate < 3% |

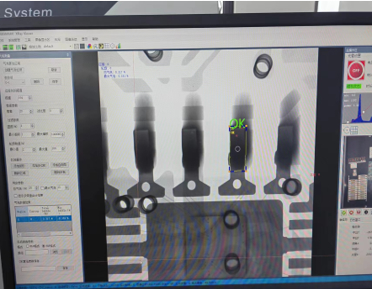

| High-Lead SMT Void Rate (X-Ray) | Single Void Rate < 1% |

Target Applications

- Military Electronics

- Aerospace Electronics

- Automotive Electronics

- High-Power LED Products

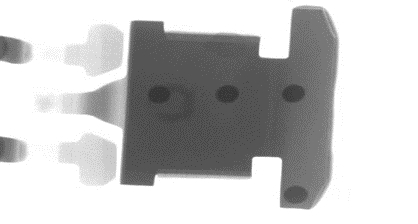

- IGBT Packaging

Soldering performance with high-power components: individual void rate is less than 1%, and the overall void rate is less than 3%.

Exceptional soldering performance is achieved with high-lead SMT components. X-ray testing reveals a single void rate consistently below 1%.

Test the effect of automotive electronic product mounting and soldering.

Test effect of vacuum soldering of chips for military, aerospace & aviation electronic products and tin sheets.