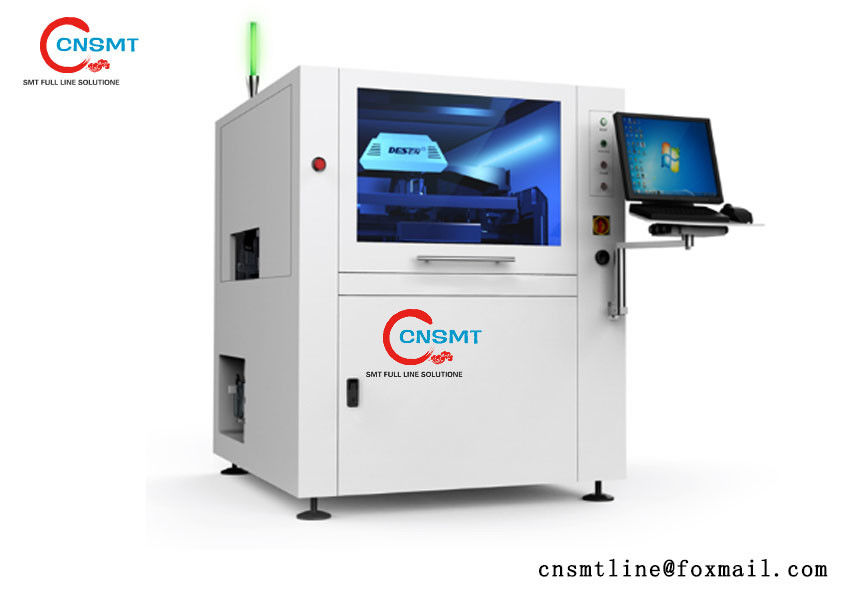

High Precision Automatic Stencil Printer With Smart Transmission System

-

Highlight

smt stencil machine

,stencil printer machine

-

BrandCnsmt

-

MODELDc6510

-

Weight2000KG

-

Lead TimeIN Stork

-

PackingWoodenbox

-

CONditionWorking

-

POWER220V 110V

-

PAYMENT TERMT/T, Paypal, Westernunion Are All Allowed

-

Place of Originchina

-

Brand Namecnsmt

-

CertificationCE

-

Model Numberclassic1008

-

Minimum Order Quantity1

-

Price10000USD/PCS

-

Packaging Detailswoodenbox

-

Delivery Time5-7 work days

-

Payment TermsT/T, Western Union

-

Supply Ability10pcs/day

High Precision Automatic Stencil Printer With Smart Transmission System

Automatic SMT Solder Paste Printer High Precision Stencil Printer With good Price cnsmt

Product features

Automatic visual alignment system

Multi-functional image processing system

Unique scraper self-adaptive system

Dripping automatic cleaning system

Smart transmission system

Early warning for maintenance

Printing parameter intelligent module

Userfriendly operation interface

| precision | Printing precision | ≥2 Cpk@±25μm@,6σ |

|

Repeat printing |

≥2 Cpk@±10μm@,6σ | |

|

Cycling time |

7s | |

|

Screen frame |

Screen frame dimension |

470*370mm-737*737mm |

|

Screen frame fixation |

air cylinder |

|

|

Screen frame adjustment |

automatic |

|

|

Platform |

platform adjustment range |

X:±4mm Y:±6mm |

|

Platform adjustment angle |

Z:±2° | |

| PCB |

printing size |

standard: Min50*50mm Max400*340mm(optional: 460*340mm) |

|

PCB thickness |

0.4mm-5mm | |

|

PCB weight |

≤3kg | |

|

PCB warping |

maximum warping 7mm (including base plate ) |

|

|

Transmission |

Transmission direction |

L→R,L→L,R→L,R→R |

|

Transmission speed |

100-1500mm/s programmable adjustment |

|

|

Transmission width |

50-340mm | |

|

Demould |

Demould method |

First use scraper, then demould, demould then use scraper, maintain pre-pressure for demould (surface demould, line demould) |

|

Demould speed

|

0.1-20mm/s | |

|

Speed distance |

0mm-3mm | |

|

Work condition |

voltage |

220V, ±10%, single phase 50/60Hz |

|

Power |

3kw | |

|

Air pressure |

0.45-0.6MPa | |

|

Gas consumption |

0.5ml/s | |

|

Safety performance |

insulation resistance |

1KV/3MΩ |

|

Ground resistance |

≤0.1Ω | |

|

Operation noise |

≤87dB | |

|

External dimension |

1140mm(L)*1360mm(W)*1505mm(H) | |