SMT Pick And Place Machine Optimum Power Supply AC 200/208/220/240/380/415V 50/60Hz 3Phase Max 5.0KVA

-

Highlight

SMT pick and place machine with power supply

,3Phase SMT placement machine 5.0KVA

,SMT machine AC 200-415V 50/60Hz

-

Chip Speed100,000 CPH (max)

-

Mounter SizeL 1,430 X D 1,900 X H 1,994

-

Pressure0.5-0.7MPa (5-7kgt/cm2) 350NL/min, 50NL/min

-

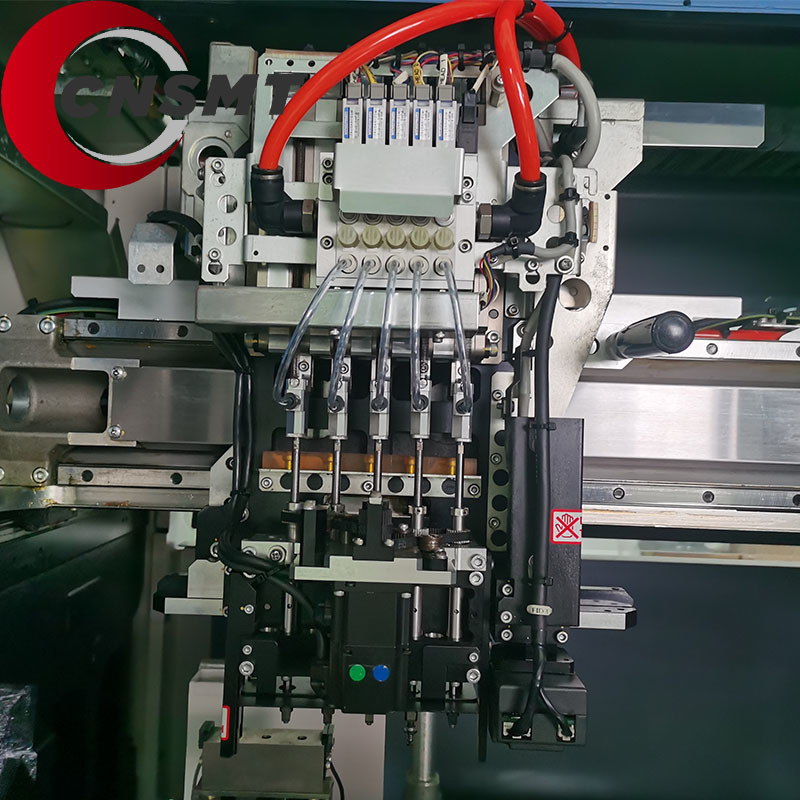

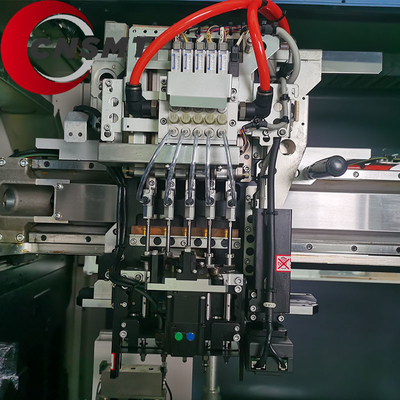

Number Of Mounting Shafts2 Gantry * 10 Spindle / 100,000 CPH (Optimum)

-

Accuracy±22 μm @ Cpk ≥ 1.0

-

Power SupplyAC 200/208/220/240/380/415V (50/60Hz 3Phase) Max 5.0KVA

-

ModelHANWHA XM520

-

Place of OriginJAPAN

-

Brand NameJUKI

-

CertificationCE

-

Model NumberKE2050M KE2050CM

-

Minimum Order Quantity1

-

Pricenegotiation

-

Packaging Detailswoodenbox

-

Delivery Time5-7 work days

-

Payment TermsT/T, Paypal, Westernunion are all allowed

-

Supply Ability10pcs/day

SMT Pick And Place Machine Optimum Power Supply AC 200/208/220/240/380/415V 50/60Hz 3Phase Max 5.0KVA

The JUKI Pick And Place Machine is a top-of-the-line Automatic Pick And Place Machine designed to meet the demanding requirements of modern electronics manufacturing. With exceptional precision and efficiency, this ASM Pick And Place Machine delivers unparalleled performance for high-volume production.

One of the key highlights of the JUKI Pick And Place Machine is its remarkable accuracy, boasting an impressive ±22 μm @ cpk ≥ 1.0. This level of precision ensures that components are placed with utmost accuracy, resulting in high-quality assembly and reliable performance of electronic devices.

When it comes to PCB Thickness compatibility, this cutting-edge machine supports a wide range from 0.38mm to 4.2mm. Whether you are working with standard PCBs or thicker substrates, the JUKI Pick And Place Machine can handle various board thicknesses with ease, making it a versatile choice for different manufacturing needs.

Equipped with advanced Automatic functionality, the JUKI Pick And Place Machine streamlines the assembly process by automatically picking and placing components onto the PCB. This automation not only boosts productivity but also reduces the margin of error, ensuring consistent and reliable results in every production run.

In terms of Dimension, the JUKI Pick And Place Machine features a compact yet robust design, measuring 1,430mm in length, 1,900mm in depth, and 1,994mm in height. This space-efficient footprint allows for seamless integration into manufacturing facilities while providing ample working space for efficient operation and maintenance.

When it comes to Component Range compatibility, the JUKI Pick And Place Machine supports a wide variety of component sizes. From tiny 0201 components to larger □22 mm (Fly) components, as well as up to L150 x 55 mm components on the stage, this machine offers the flexibility to handle diverse component types and sizes, catering to a range of production requirements.

- Product Name: SMT Pick And Place Machine

- Brand: HANWHA

- PCB Thickness: 0.38-4.2mm

- Chip Speed: 100,000 CPH (max)

- Spindle & Speed: 2 Gantry * 10 Spindle / 100,000 CPH (Optimum)

- Product Category: SMT Pick And Place Machine

| Pressure | 0.5-0.7MPa (5-7kgt/cm2) 350NL/min, 50NL/min |

| Spindle & Speed | 2 Gantry * 10 Spindle / 100,000 CPH (Optimum) |

| Component Range | 0201 ~ □22 mm (Fly) / ~ L150 x 55 mm (Stage) |

| Dimension (L x D x H) | 1,430 x 1,900 x 1,994 mm |

| Mounter Size | L 1,430 X D 1,900 X H 1,994 |

| Product Name | HANWHA XM520 NEW P&P Machine |

| Brand | HANWHA |

| Model | HANWHA XM520 |

| Automatic/Manual | Automatic |

| Power Supply | AC 200/208/220/240/380/415V (50/60Hz 3Phase) Max 5.0KVA |

The JUKI SMT Pick And Place Machine, including models KE2050M and KE2050CM, is a top-of-the-line product designed for a wide range of product application occasions and scenarios. With its CE certification and origin from Japan, this machine guarantees high quality and reliability.

Perfect for small-scale production or large-scale manufacturing, this Automatic Pick & Place Machine by JUKI offers exceptional placement accuracy of ±28μm, making it suitable for precision electronic assembly tasks.

Whether you are working on PCB assembly for consumer electronics, automotive components, LED lighting, or any other electronic devices, the JUKI SMT Pick And Place Machine is the ideal choice. Its fast operation and efficiency make it the Fastest Pick And Place Machine in its category.

With a minimum order quantity of just 1 unit and flexible payment terms including T/T, Paypal, and Western Union, procuring this ASM Pick And Place Machine is hassle-free. The supply ability of 10 units per day ensures that your production needs are met promptly.

When it comes to delivery, you can expect your JUKI SMT Pick And Place Machine to arrive within 5-7 work days, securely packaged in a wooden box. The product category of this machine is SMT Pick And Place Machine, emphasizing its specialized function.

Enhance your manufacturing process with the HANWHA XM520 NEW P&P Machine, a model under the JUKI brand. This innovative Pick And Place Machine, with dimensions of 1,430 x 1,900 x 1,994 mm, offers advanced features for increased productivity and precision.

The Product Technical Support and Services for the SMT Pick And Place Machine include:

- Installation and setup assistance

- Training for operators and maintenance staff

- Troubleshooting guidance for machine issues

- Software updates and upgrades

- Spare parts supply and replacement services

- On-site repair and maintenance services

The SMT Pick And Place Machine is carefully packaged to ensure safe delivery to our customers. Each machine is securely cushioned and protected to prevent any damage during transit. Additionally, the packaging is designed to be compact and efficient to minimize shipping costs.