Black SMD BGA Rework Station High Performance With Accurate Temperature

-

Highlight

pcb coating machine

,bga rework machine

-

BrandCnsmt

-

MODELCN018

-

Weight41KG

-

Lead TimeIN Stork

-

PackingVacuum Woodenbox

-

CONditionWorking

-

POWER220V 110V

-

PAYMENT TERMT/T, Paypal, Westernunion Are All Allowed

-

Place of Originchina

-

Brand Namecnsmt

-

CertificationCE

-

Model NumberCN018

-

Minimum Order Quantity1

-

Pricenegotiation

-

Packaging Detailswoodenbox

-

Delivery Time5-7 work days

-

Payment TermsT/T, Western Union

-

Supply Ability10pcs/day

Black SMD BGA Rework Station High Performance With Accurate Temperature

Smt Line Machine BGA Rework Station smd pcba repair machine semi-Auto For iphone ipad Macbook Logic Board Repair

High-quality heating core structure is reasonable design, fine workmanship, symmetry, long service life

After the airflow passes through the heater core, the temperature is even and the wind speed is gentle.

new BGA rework station fully uses German imported materials, superior performance

1. Evenly out of the wind to ensure that the four corners of the chip solder melt simultaneously

2. Accurate temperature, not bake chips

3. Do not need to dry circuit boards and chips before desoldering chips

4. Long service life, 3 years replacement

Problems with inferior heater cores:

1. The wind is not uniform, after soldering, the chip does not melt while the solder melts.

2. Partial solder joints after welding

3. After the circuit board is repaired, it is re-welded in a short time

4. During the welding process, the chip is bent, bulged, sunken, blistering, abnormal sound

5. The circuit board must be dried prior to welding, otherwise the success rate of welding cannot be guaranteed.

6. Short service life, easy to burn out, need to be replaced regularly

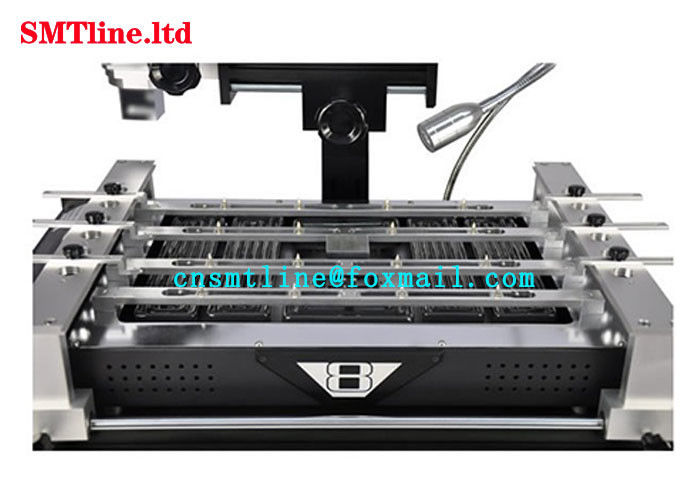

The picture above is the stencil of the tuyere

The size of the steel mesh is carefully calculated, the middle hole is small, and the surrounding holes are large.

This design allows the hot air blown by the tuyere to be about 5 degrees cooler than the ambient temperature.

This hot air feature is very beneficial to protect the chip, to avoid chip damage at high temperatures.

| Performance indicators and specifications parameters: |

| The repair station is suitable for the repair of circuit boards such as notebook computer motherboards, desktop computer motherboards, IPC motherboards, communication equipment motherboards, and LCD TVs. |

| The rework station adopts a three-zone design and the heating process is stable. |

| The rework station's preheating table area is 485mm*405mm. |

| This rework station adopts segmented heating method, which can be divided into 8 segments for heating. It can store 10 groups of temperature curves. |

| The rework station is positioned through a V-shaped card slot, giving away a discrete fixture that can position a circuit board with a complex structure. |

| This rework station is equipped with a high-power cross-flow fan to quickly cool the circuit board. |

| This rework station is equipped with high-grade work lights for lighting. |

| This rework station has an audible alarm function. |

| The rework station is equipped with 5 tuyere, up to 775 CPU seats, small to memory particles, can be welded. |

| Dimensions: Length 645mm × width 530mm × height 450mm. |

| Use power: 220V 50/60HZ. |

| Machine power: 3200W. |

|

Machine weight: 41 kg.

|

![]()