SMT Selective Auto Coating Machine , Smart Conformal Industrial Coating Machine

-

Highlight

pcb coating machine

,bga rework machine

-

BrandCnsmt

-

MODELCnsmt12

-

Weight100KG

-

Lead TimeIN Stork

-

PackingWoodenbox

-

CONditionWorking

-

POWER220V 110V

-

PAYMENT TERMT/T, Paypal, Westernunion Are All Allowed

-

Place of Originchina

-

Brand Namecnsmt

-

CertificationCE

-

Model Numbercnsmt12

-

Minimum Order Quantity1

-

Price500USD/PCS

-

Packaging Detailswoodenbox

-

Delivery Time5-7 work days

-

Payment TermsT/T, Western Union

-

Supply Ability10pcs/day

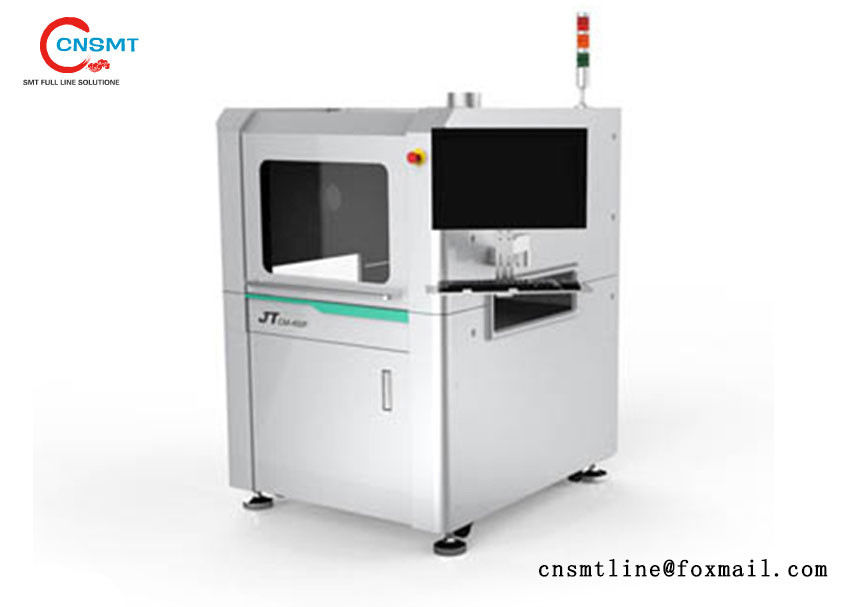

SMT Selective Auto Coating Machine , Smart Conformal Industrial Coating Machine

Selective Conformal Coating Machine

Introduction & Description

Automatic conformal coating system is designed for the smart, automatic, selective coating of conformal coating material. This automatic conformal coating system integrates the sciences and technologies of hydrodynamics, spraying and coating technologies, motor control technology, which has a good performance of automation, high accuracy, high efficiency, and high stability.

Application & Solution

Processing Function:

Conformal coating, dam process, solder mask coating, DIP component bonding.

Industrial Application:

[LED industry][auto electronic industry][medical equipment] [telecommunication industry]

[electrical appliance industry][electronic industry] [mechanical & electrical industry]

Technical Parameters

| Machine Name | 4-Axis Selective Conformal Coating Machine |

| Machine Model | lmeTTech 430 |

| Overall Dimension (L×W×H) | 1300×1100×1700 mm |

| Gross Weight | 800 kg |

| Control System | Industrial PC & Motion Controller |

| Operation System | Industrial IPC With WINDOWS XP System/Above |

| Programming Method | Manual Teaching Or CAD Data Imported |

| Total Axes Quantity | 4-Axis Motion System (X,Y,Z,U Axis) |

| X,Y Axis Drive Method | Servo Motor & Motorized Cylinder |

| X,Y Axis Motion Velocity | 1500 mm/s |

| X,Y Axis Poisitioning Accurate | 0.2 mm |

| Z- Axis Drive Method | Servo Motor & High Precise Screw Modular |

| Z-Axis Positioning Accuracy | 0.02 mm |

| Z- Axis Motion Velocity | 1000 mm/s |

| U-Axis Drive Method | Servo Motor & Speed Reducer Driven |

| U-Axis Position Accuracy | 0.1° |

| U-Axis Rotation Angle | ±180° |

| Tilting Drive Method | 3 SMC Rotary Cylinders Driven |

| Tilting Angle | 0-90 °(Available To Set) |

| Coating Head Quantity |

Total 3 Coating Heads;Pin Dispensing Coating Head/ 1; Medium-Size Atomized Coating Head/1; Large-Size Atomized Coating Head/1 |

| Coating Head Up-Down | Dual-Rod Pneumatic Cylinder Driven |

| Coating Width |

Pin Dispensing Coating Head, Min. Coating Width:2 mm Medium-Size Atomized Coating Head, Coating Width: 6-8 mm |

| Pin Coating Head Size | 0.8 mm |

| Coating Thickness | 0.03 – 1 mm |

| Edge Clearance | ±0.5 mm |

| PCB Conveying Height | 920±20 mm |

| Conveying Speed | 10000 mm/min. |

| Conveying Direction | L-R (R-L) |

| Conveyor Motor | AC 220 V, 40 W |

| PCB Width Available | 50-450 mm |

| Lane Widen Method | Manual Widen |

| PCB Size | Max. W/L 450 ×450 mm (Custom Available) |

| Component Height (On PCB) | Max.70 mm |

| Pressure Tank |

10 L Pressure Tank To Storage And Supply Conformal Coating; 3-5 L Pressure Tank To Storage And Supply Coating Diluent; |

| Coating Head Clean | Automatic Dip-Purge Cup |

| Air Blower Power | AC 220V, 50/60Hz, 750 W |

| Air Flow | 120 m³/H |

| Internal Light System | Equipped With Internal Lighting Lamp |

| UV Inspection Light | Equipped With Internal UV Lightng Lamp |

| Air Source | 4-6kgf/cm2 |

| Power Source | AC 220V, 1 Phase |

| Total Power Consumption | 2.2 KW |

| Barcode Scanning System | To Scan Barcode On PCB And Select Program File For Coating (Optional) |

| CCD Camera | CCD Camera To Assist Position (Optional) |

| Motorized Convey Widen | Motor Drive To Widen Convey Width (Optional) |

Feature & Performance

Auto-Control System

Highly systematic control system is designed with IPC, motor motion card, independently-developed software system, in-line or off-line program method.

Programming System

Visual in-line programming system can complete the programming requirement for paths of dot, line, round, arc.

Mechanical Frame System

Metal plate or aluminum material is processed for the mechanical frame system for the automatic conformal coating system with its design complies with the human engineering.

Entire Motion System

4- Axis is introduced for this automatic conformal coating system, servomotor functions as the main driven power for X, Y, Z ,U axis, more stable, more accurate.

Coating Nozzle System

In the automatic conformal coating system, the biaxial cylinder driven system is introduced for the nozzle driven, 60-160mm is available for adjustment.

Auto-Conveying System

Motor & gearbox are designed into conveying system for the automatic conformal coating system, with velocity 10000m/min, Chain drive structure with the conveying width up to 50-450mm.

Material Supply System

10L pressure tank is introduced for the liquid storage and output system, liquid weight sensing system equipped functions to alarm if liquid in insufficient.

Air Draft System

Silent air blower direct discharge the exhausted gas and ensure the clean operation environment.

Nozzle Clean System

Stainless steel cups that made in special design for the dipping and purge in the processing interval that prevents the nozzle from block.

Internal Light System

The conformal coating system is designed with lighting system as well as the UV inspection lighting system for processing inspection.

![]()