KHW-M712M-00X Yamaha YG100R SMT Machine Z-axis Motor Aluminum Block Bracket

-

BrandYamaha

-

ModelKHW-M712M-00X Yamaha YG100R SMT Machine Z-axis Motor Aluminum Block Bracket

-

Capayity1009

-

Mounter Weight0.79kg

-

Mounter Size56

-

SupplierSMTLINE

-

ConditionNew

-

Place of OriginJapan

-

Brand NameYAMAHA

-

CertificationYAMAHA Vibration Vibration Fit YV YS

-

Model NumberKHW-M712M-00X Yamaha YG100R SMT Machine Z-axis Motor Aluminum Block Bracket

-

Minimum Order Quantity1

-

Pricenegotiation

-

Packaging DetailsWoodenbox

-

Delivery Time1-2 work days

-

Payment TermsT/T,Western Union,paypal

-

Supply Ability10pcs/day

KHW-M712M-00X Yamaha YG100R SMT Machine Z-axis Motor Aluminum Block Bracket

KHW-M712M-00X Yamaha YG100R SMT Machine Z-axis Motor Aluminum Block Bracket

KHW-M712M-00X Z-Axis Motor Aluminum Bracket – Yamaha YG100R SMT Machine

Overview

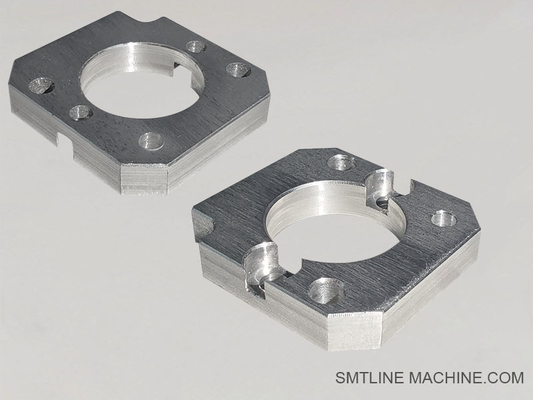

The KHW-M712M-00X is a Z-axis motor mounting bracket made of precision-machined aluminum, designed for use in the Yamaha YG100R pick-and-place machine. This bracket secures the Z-axis motor to the placement head or gantry system, ensuring stability, accurate vertical movement, and alignment during high-speed component placement.

Key Features

Part Number: KHW-M712M-00X

Machine Compatibility: Yamaha YG100R SMT machine

Function:

Mounts and aligns the Z-axis motor (vertical axis)

Ensures mechanical stability during nozzle up/down motion

Helps reduce vibration and positioning errors

Material: High-strength, lightweight aluminum alloy

Design: Precision CNC-machined with mounting holes and motor interface slots

Finish: Anodized or anti-corrosion treated (varies by batch)

Applications

Supports the Z-axis motor responsible for raising/lowering the pick-up nozzle

Maintains structural rigidity under dynamic load conditions

Used in maintenance, retrofits, or machine head repair of Yamaha YG100R series

Installation Notes

Must be installed with proper torque on mounting screws

Alignment with the motor shaft and Z-axis sensor is critical for accurate operation

Recommend pairing with original Yamaha motor and fasteners for optimal fit

Summary

The KHW-M712M-00X aluminum bracket is an essential mechanical component for the Z-axis system of Yamaha YG100R pick-and-place machines. It provides reliable support and precise alignment for the vertical motor, ensuring smooth and accurate component placement in demanding SMT production environments.

Related Accessories for KHW-M712M-00X (Z-Axis Motor Bracket)

| Category | Example Part Number | Description |

| Z-Axis Motor (Servo) | KHW-M7106-00 / KHY-M7106-00 | Main motor mounted on the aluminum bracket to control vertical (Z-axis) motion |

| Z-Axis Linear Rail / Guide | KHY-M7103-00 | Linear guide rail for stable and precise Z-axis movement |

| Ball Screw or Lead Screw | KHW-M7101-00 | Transfers rotary motion to linear motion for the Z-axis |

| Motor Coupling | KHW-M7123-00 | Connects the Z-axis motor shaft to the lead screw |

| Z-Axis Sensor | KHW-M7109-00 (example) | Detects top/bottom limits or home position of the Z-axis |

| Mounting Screws & Hardware | Standard Yamaha M3/M4 types | Fasteners used to secure the bracket and motor assembly |

| Head Unit Assembly | KHX-M7100-00 (for YG100R) | The full placement head unit where the bracket and motor are installed |

Notes:

These accessories ensure precise Z-axis movement, critical for accurate pick-and-place performance.

Always use genuine Yamaha parts to maintain mechanical alignment and reliability.

If you provide your YG100R head type (e.g., single-gantry or dual-head), more exact part numbers can be recommended.

Related Part Numbers – KHW-M712M-00X and Z-Axis Assembly (YG100R)

| Part Number | Description |

| KHW-M712M-00X | Z-axis motor aluminum bracket (main mounting base) |

| KHW-M7106-00 | Z-axis motor (servo motor for vertical nozzle movement) |

| KHW-M7101-00 | Z-axis ball screw or lead screw (linear motion mechanism) |

| KHW-M7123-00 | Motor coupling (connects Z-motor shaft to lead screw) |

| KHW-M7103-00 | Z-axis linear guide (ensures stable up/down movement) |

| KHW-M7109-00 | Z-axis limit sensor or home position sensor |

| KHX-M7100-00 | Head unit assembly (where bracket is installed) |

| KHW-M7111-00 | Nozzle holder base (installed below the Z-axis bracket) |

| KHW-M7125-00 | Spacer or support frame for Z-axis components |

| KHW-M7128-00 | Bracket locking plate or fixing cover |

| Standard Yamaha screws | M3, M4 machine screws (for bracket mounting) |

Notes:

These part numbers are standard for Yamaha YG100R, but specific models or head configurations may differ slightly.

Always cross-check with the machine BOM or maintenance manual to confirm part compatibility.

Original Yamaha parts are highly recommended for precision alignment and durability.

![]()

FAQ Guide — KHW-M712M-00X Z-Axis Motor Bracket (Yamaha YG100R)

1. What is the KHW-M712M-00X used for?

It is an aluminum bracket that mounts and secures the Z-axis motor on the Yamaha YG100R placement head, enabling precise up/down motion of the nozzle during component pickup and placement.

2. Which machines use this bracket?

Primarily used in Yamaha YG100R pick-and-place machines. It may also be found in similar-generation models or customized heads with the same Z-axis design.

3. What is the function of the Z-axis bracket?

Fixes the Z-axis motor in place

Maintains alignment with the lead screw or ball screw

Supports stable and accurate vertical movement of the head/nozzle assembly

4. What material is it made from?

Made from precision-machined aluminum alloy, offering high strength, low weight, and corrosion resistance. This ensures stability without adding excess load to the head.

5. How do I know if the bracket is damaged?

Common symptoms include:

Loose or misaligned Z-axis motor

Inconsistent nozzle height or positioning errors

Visible cracks, warping, or stripped screw holes on the bracket

6. Can I replace the bracket myself?

Yes — if you're a trained technician. Replacement requires:

Disassembling the Z-axis motor and lead screw

Removing the old bracket and mounting the new one

Realigning the motor and verifying nozzle calibration

7. What other parts should I inspect when replacing the bracket?

Z-axis motor (KHW-M7106-00)

Coupling (KHW-M7123-00)

Lead screw or ball screw (KHW-M7101-00)

Z-axis sensor (KHW-M7109-00)

Linear guide (KHW-M7103-00)

Mounting screws and frame alignment

8. Is calibration required after replacement?

Yes. After replacing the bracket and reassembling the motor, the Z-axis position must be recalibrated using Yamaha’s machine interface to ensure accurate pickup heights.

9. Where can I get a replacement bracket?

Order from official Yamaha SMT parts distributors, or authorized resellers. Always use original parts to ensure fit, material strength, and machine compatibility.

Physical warehouse,

fast delivery

after-sales support

providing door-to-door transportation services

price advantages,

offering a full range of SMT dip equipment and accessories

We can do for you:

1. We provide fulL SMT solution for you

2. We provide core technology with our equipments

3. We provide the most professional tech service

4. We have wealthy experience on SMT factory setup

5. We can solve any question about SMT

![]()

Contact:

CNSMT Electronics Equipment Co,.LTD

Email: info@smtlinemachine.com

www.smtlinemachine.com

Mb/whatsapp/wechat:+8613537875415

SKYPE:smtdwx