-

BrandSMTLINE

-

ModelSamsung Pneumatic Feeder 32mm

-

Capayity1009

-

Mounter Weight0.79kg

-

Mounter Size56

-

SupplierSMTLINE

-

ConditionNew

-

Place of OriginChina

-

Brand Namesmtline

-

CertificationYAMAHA Vibration Vibration Fit YV YS

-

Model NumberSamsung Pneumatic Feeder 32mm

-

Minimum Order Quantity1

-

Pricenegotiation

-

Packaging DetailsWoodenbox

-

Delivery Time1-2 work days

-

Payment TermsT/T,Western Union,paypal

-

Supply Ability10pcs/day

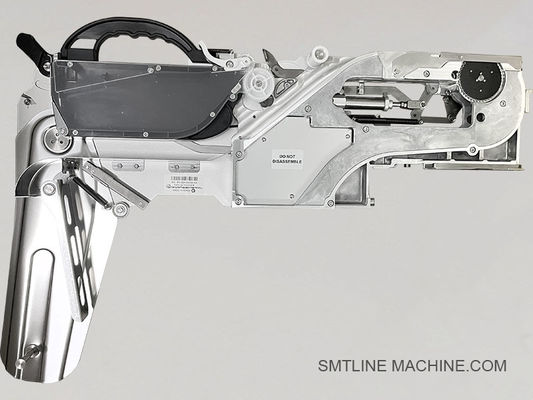

Samsung Pneumatic Feeder 32mm

Samsung Pneumatic Feeder 32mm

Product Introduction – Samsung 32mm Pneumatic Feeder

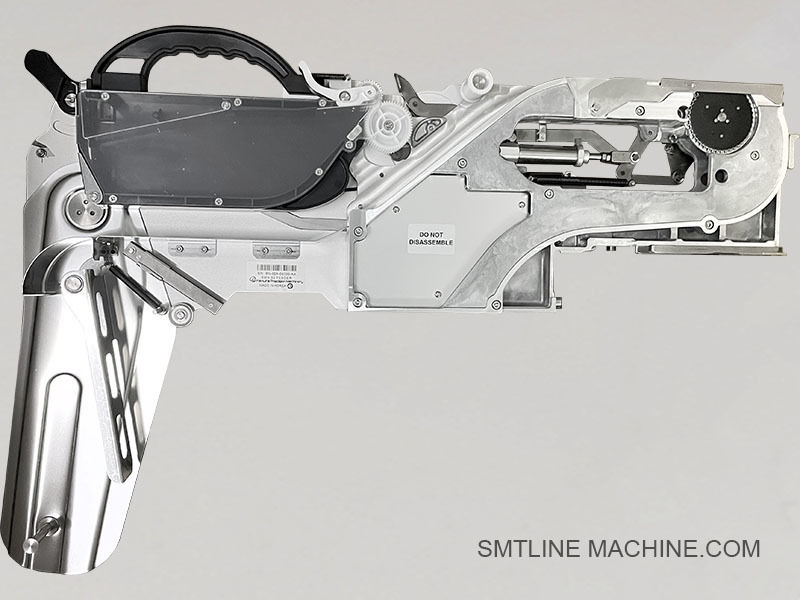

The Samsung 32mm Pneumatic Feeder is a robust, air-driven component tape feeder designed to supply large and heavy electronic components to Samsung CP-series SMT placement machines. It utilizes compressed air to control the tape indexing mechanism, ensuring precise, high-speed feeding for 32mm-wide carrier tapes.

Key Features

Pneumatic operation: Uses compressed air to advance the tape step-by-step

Designed for large SMD components such as:

Power ICs

Transformers

Connectors

Shielded inductors

Compatible with Samsung CP-series machines, including CP40, CP45, CP60

Supports fast and stable feeding in high-volume production environments

Rigid construction for durability and long-term stability

Technical Specifications

Tape Width: 32mm

Drive Method: Pneumatic (air cylinder mechanism)

Feeding Pitch: Adjustable (typically 8, 12, or 16mm steps)

Power Supply: Requires compressed air (0.4–0.6 MPa recommended)

Reel Size Compatibility: Standard 13” and 15” carrier reels

Applications

Widely used in industries such as:

Automotive electronics

Power modules

Industrial control PCBs

Ideal for placing large components that require wider tape and stable feed force

Compatibility

Fully compatible with Samsung CP-series pneumatic feeder platforms:

CP40 / CP40L

CP45 / CP45FV / CP45NEO

CP60 series

Related Accessories – Samsung 32mm Pneumatic Feeder

1. Mechanical Components

32mm Tape Guide Rail

Ensures stable alignment of wide tape during feeding.

Helps prevent skewing or misalignment of large components.

Cover Tape Separator / Pusher Assembly

Peels back and holds the cover tape to expose components.

May be larger and reinforced for wide tapes.

Upper Cover Plate

Holds down the component tape for smooth advancement.

Feeder Lock Pin / Locking Knob

Mechanism that secures the feeder to the feeder bank rail.

Reel Holder Shaft / Bracket

Holds the 13” or 15” component tape reel securely in place.

2. Pneumatic Components

Large-Bore Air Cylinder

Drives the tape feed stroke for 32mm-wide tape.

Heavier-duty than 8mm or 12mm versions.

Air Push Rod / Slide Linkage

Connects cylinder motion to the tape-advancing gear.

Return Spring

Resets the mechanism after each feed stroke.

Air Hose Fittings / Tube Connectors

Push-to-connect or threaded fittings for air input.

Exhaust Muffler / Silencer (Optional)

Reduces pneumatic noise during air release.

3. Testing & Maintenance Tools

Feeder Calibration Jig

Used to test and adjust the feeding action off-line.

Manual Test Box

Allows technicians to simulate feeding with compressed air.

Storage Rack / Feeder Cart

Organizes and stores wide feeders safely.

Cleaning Brushes / Tools

Used to clean the tape path and internal mechanisms.

Notes

Many accessories are shared with 24mm and 44mm pneumatic feeders but vary slightly by size.

All guide rails, air cylinders, and brackets must match the 32mm feeder frame type to ensure proper performance.

Related Part Numbers – Samsung 32mm Pneumatic Feeder (No Table)

Mechanical Components

J66021004A – 32mm Tape Guide Rail, for aligning and supporting the wide tape path.

J66011005A – Cover Tape Pusher Assembly, designed for lifting and separating the cover tape on 32mm tapes.

J66031013A – Upper Cover Plate, reinforced to handle wider tape pressure.

J70613008A – Feeder Locking Pin or Locking Knob, for mounting the feeder to the machine.

J66031019A – Reel Shaft Bracket or Reel Holder, to support 13” or 15” component tape reels.

J66031023A – Clamp Spring or Tension Spring Plate, maintains consistent tape pressure and alignment.

Pneumatic Components

J70541006A – Air Cylinder (Large-Bore Type), provides the force to index heavy 32mm tape.

J70631011A – Air Push Rod or Slide Link, connects the cylinder to the tape advance mechanism.

J90651008A – Return Spring (Heavy-duty), used to reset the feeder's slider after each cycle.

J70631015A – Air Tube Connector, quick-fit or push-to-connect type for pneumatic lines.

J70631012A – Cylinder Mount Bracket, holds the air cylinder in position inside the feeder.

Test & Maintenance Tools

J13013001A – Feeder Calibration Jig, for testing and aligning the feeder off-machine.

J13014002A – Manual Feeder Test Box, simulates air feed manually for functional checks.

J13012003A – Feeder Storage Rack or Trolley, for safe feeder organization.

J13014004A – Cover Tape Rewind Reel Assembly, optional device to collect used cover tape.

![]()

FAQ Guide – Samsung 32mm Pneumatic Feeder

1. What is the Samsung 32mm Pneumatic Feeder used for?

The Samsung 32mm pneumatic feeder is used to feed large surface-mount components—such as power ICs, relays, connectors, and shielded inductors—mounted on 32mm-wide carrier tape into Samsung CP-series SMT machines.

2. Which machines is it compatible with?

This feeder is compatible with the following Samsung pick-and-place machines that use pneumatic feeders:

CP40 / CP40L

CP45 / CP45FV / CP45NEO

CP60 Series

3. How does the feeder work?

It uses a compressed air-driven cylinder to advance the component tape one step at a time. The air cylinder moves a push rod that drives the tape advancement gear, exposing the next component for pick-up.

4. What air pressure is required?

The recommended working pressure is 0.4 to 0.6 MPa (4–6 bar).

Low pressure may cause incomplete feeding; high pressure can lead to mechanical wear or tape breakage.

5. What types of tape and components can it handle?

Tape Width: 32mm

Component Types:

Power semiconductors

Large capacitors

Transformers

High-current connectors

Relay packages

Tape Type: Embossed plastic carrier tape with or without cover tape rewind

6. What are common issues and troubleshooting suggestions?

Tape not feeding

Check for low air pressure or a damaged air cylinder.

Cover tape not peeling correctly

Inspect and replace the cover tape pusher or tension spring.

Feeder does not lock into machine

Check the lock pin or mounting latch for damage.

Feeder returns slowly or sticks

Clean the slide linkage and inspect the return spring.

Air leakage

Replace worn air tube connectors or seals.

7. Which parts frequently require replacement?

Air Cylinder (J70541006A)

Return Spring (J90651008A)

Cover Tape Pusher (J66011005A)

Tape Guide Rail (J66021004A)

Feeder Locking Pin (J70613008A)

Air Connector (J70631015A)

8. How to test the feeder?

Use a feeder test jig (J13013001A) or a manual feeder test box (J13014002A) to verify air stroke and tape advancement outside the SMT machine.

9. Does it support cover tape rewind?

Some configurations may support optional cover tape rewind using a rewind reel (e.g. J13014004A), but this depends on the model version.

10. What is the suggested maintenance schedule?

Daily: Blow off dust, check tape alignment

Weekly: Inspect for air leaks, clean moving parts

Monthly: Lubricate mechanical joints and check spring tension

Quarterly: Replace worn parts and test with jig for accuracy

Physical warehouse,

fast delivery

after-sales support

providing door-to-door transportation services

price advantages,

offering a full range of SMT dip equipment and accessories

We can do for you:

1. We provide fulL SMT solution for you

2. We provide core technology with our equipments

3. We provide the most professional tech service

4. We have wealthy experience on SMT factory setup

5. We can solve any question about SMT

![]()

Contact:

CNSMT Electronics Equipment Co,.LTD

Email: info@smtlinemachine.com

www.smtlinemachine.com

Mb/whatsapp/wechat:+8613537875415

SKYPE:smtdwx