-

Highlight

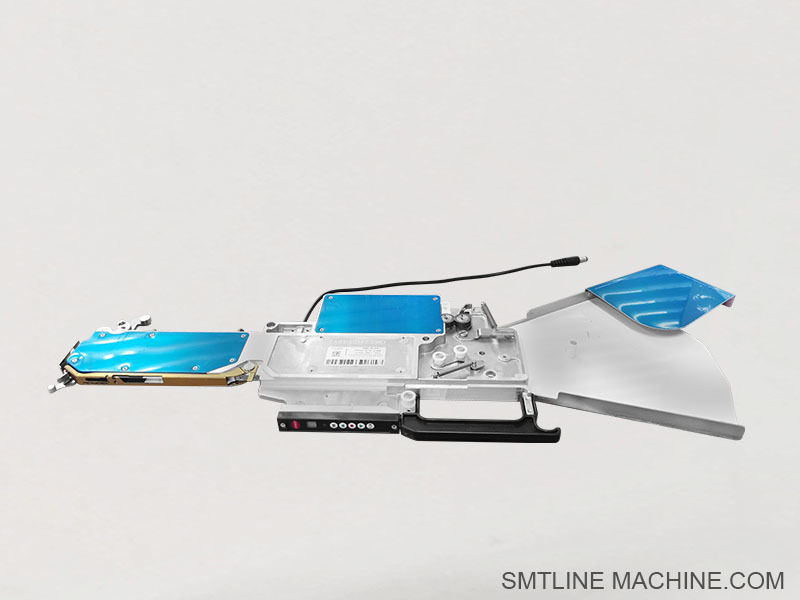

CWEF-YE8-V7

,Component Mounting Feeder

,CWEF-YE8-V7 Feeder

-

BrandSMTLINE

-

ModelSamsung Feeder CWEF-YE8-V7

-

Capayity1009

-

Mounter Weight0.79kg

-

Mounter Size56

-

SupplierSMTLINE

-

ConditionNew

-

Place of OriginChina

-

Brand Namesmtline

-

CertificationYAMAHA Vibration Vibration Fit YV YS

-

Model NumberSamsung feeder CWEF-YE8-V7

-

Minimum Order Quantity1

-

Pricenegotiation

-

Packaging DetailsWoodenbox

-

Delivery Time1-2 work days

-

Payment TermsT/T,Western Union,paypal

-

Supply Ability10pcs/day

Precision Samsung CWEF-YE8-V7 Feeder for Efficient Component Mounting

Samsung feeder CWEF-YE8-V7

Product Introduction – Samsung CWEF‑YE8‑V7 Feeder

The Samsung CWEF‑YE8‑V7 is a high-performance 8 mm electrical feeder designed for seamless integration with Samsung/Hanwha SMT machines (gear like SM/CP/SE series). This intelligent feeder reliably advances tape reels for chip resistors, capacitors, and small passive components during high-speed SMT assembly.

Key Features

Electric drive system ensures precise feeding with adjustable pitch settings—no pneumatic air needed

8 mm tape compatibility, standard format for commonly used chip components

SME/SM/CP/Hanwha compatibility, widely supported across Samsung pick-and-place platform ecosystems

Reliable encoder and sensor integration, preventing tape misfeeds and improving component pick accuracy&x20;

Compact and robust construction, designed to fit densely packed feeder banks and support quick changeovers

Typical Specifications

Tape width: 8 mm (standard)

Feeder drive: Electric motor with integrated microcontroller

Interface: Samsung/Hanwha SM/CP-style connector

Pin configuration: Typically 4- or 5-pin versions available&x20;

Mounting: Compatible with standard ECM cassette racks in Samsung / Hanwha lines

Applications

Used in Samsung / Hanwha surface-mount assembly for high-volume & precision placement

Ideal for processing chip components (0805, 0603, 1206) and small passives

Supports high-mix product runs with frequent feeder changes due to quick load/unload design

Compatibility & Purchase Options

Often sold pre-owned or refurbished via SMT parts suppliers, tested with warranty

Multiple variants available: 4-pin / 5-pin connector styles, some featuring updated V7 control logic

Commonly stocked in 8 mm CP40, SM-series, and tray feed configurations

Related Accessories – Samsung CWEF-YE8-V7 Feeder

1. Feeder Spare Parts

Feeder Cover / Cover Plate

Used to securely hold the carrier tape and prevent tangling or lifting.

Tape Guide Rail / Guide Plate

Ensures smooth and accurate feeding of the 8 mm tape during high-speed operation.

Pusher Assembly / Tape Pusher

Maintains proper pressure and alignment of the cover tape while feeding.

Tape Sensor / End Sensor

Detects the presence or end of tape; ensures accurate component pick detection.

2. Drive & Mechanical Parts

Feeder Motor / Stepper Motor Assembly

Powers the internal feeding mechanism (electric feeders use integrated motors).

Gear Set / Gearbox

Transfers torque from motor to feeder sprockets; may wear over time.

Feeder Shaft / Pin Roller Assembly

Helps rotate or stabilize the tape reel during operation.

Locking Knob / Fixing Clip

Used to secure the feeder to the feeder bank or slot on the pick-and-place machine.

3. Electrical Components

Feeder PCB (Control Board)

Manages motor logic and communicates with the SMT machine interface.

Feeder Cable / Connector Harness

Connects the feeder to the control signal and power supply (typically 4-pin or 5-pin depending on model).

Feeder Sensor Board

Optional for monitoring tape movement, cover tape position, or error detection.

4. Feeder Calibration & Maintenance Tools

Feeder Calibration Jig / Fixture

Used to test and calibrate electric feeders outside the SMT machine.

Tape Rewinder / Tape Collection Reel

Collects cover tape during feeding to prevent interference or tangling.

Cleaning Kit / Lubricants

For maintaining mechanical parts such as rollers, gears, and guide rails.

5. Feeder Rack / Storage

Feeder Storage Cart

Movable cart for organizing and storing multiple feeders.

Feeder Rack (ESD-safe)

Static-safe feeder holder for loading and unloading operations.

Related Part Numbers – Samsung CWEF-YE8-V7 Feeder

1. Mechanical Components

J66021001A – Tape Guide Rail

J66011003A – Cover Tape Pusher Assembly

J70613008A – Lock Pin / Locking Knob

J66031011A – Upper Cover Assembly

J66031017A – Side Cover Plate

2. Drive & Electrical Components

J90551427A – Feeder Motor Assembly

J90651417A – Drive Gearbox Unit

J91751403A – Motor Pulley / Coupling

J67031002A – Tape Sensor PCB

J90851407A – Feeder Main Control Board

J66011002A – Feeder Signal Cable / Connector

3. Calibration & Maintenance Tools

J13013001A – Feeder Calibration Jig / Test Fixture

J67021010A – Tape End Sensor Assembly

J66031013A – Tape Guide Fixing Bracket

J13014004A – Cover Tape Rewinder Reel

4. Optional & General Accessories

J13012003A – Feeder Storage Rack (ESD Safe)

J25052013A – Cover Tape Rewind Motor

J66031022A – Spring Plate (Compression Bracket)

J67041001A – Encoder Sensor for Tape Movement

![]()

FAQ Guide – Samsung CWEF-YE8-V7 Electric Feeder

1. What is the CWEF-YE8-V7 Feeder used for?

It is an 8mm electric feeder used to supply surface mount components (typically 0402, 0603, 0805, etc.) from tape reels to Samsung/Hanwha pick-and-place machines such as SM, CP, and DECAN series.

2. Which machines is it compatible with?

The CWEF-YE8-V7 is compatible with various Samsung/Hanwha SMT platforms, including:

SM320, SM421, SM471, SM482

CP40, CP45, CP60

DECAN S1/S2, and SME series

Check your model’s feeder bank specifications to ensure compatibility (4-pin or 5-pin versions).

3. Is it electric or pneumatic?

It is electrically driven, using a built-in motor and control PCB. No compressed air is needed, unlike older pneumatic feeders.

4. What component sizes does it support?

It supports standard 8mm tape, which is typically used for small passive components like:

0402, 0603, 0805 resistors and capacitors

Small ICs or LEDs in 8mm embossed or paper tape

5. How is the feeder powered and controlled?

The feeder connects to the machine via a 4-pin or 5-pin electrical interface and is controlled by the SMT machine’s software.

6. What are common failure symptoms?

Tape jamming or misfeeds

Motor not advancing the tape

No response or recognition from the machine

Cover tape not peeling properly

These may indicate issues with the motor, sensor, PCB, or mechanical misalignment.

7. What are the common replaceable parts?

Tape guide rail (J66021001A)

Motor assembly (J90551427A)

Gearbox (J90651417A)

Tape sensor PCB (J67031002A)

Cover tape pusher (J66011003A)

8. How is the feeder maintained?

Clean tape path regularly to avoid buildup

Check gear and motor function during downtime

Replace worn or misaligned parts immediately

Use a calibration jig to test feeder movement offline

9. Does it support cover tape rewinding?

Yes. It can be equipped with a cover tape rewind reel (e.g., J13014004A), which helps manage waste tape cleanly during production.

10. How can I identify the version or connector type?

Check the label or rear connector:

4-pin version: older machine compatibility

5-pin version: newer models or enhanced feedback systems

Also look for firmware version or "V7" marking.

Physical warehouse,

fast delivery

after-sales support

providing door-to-door transportation services

price advantages,

offering a full range of SMT dip equipment and accessories

We can do for you:

1. We provide fulL SMT solution for you

2. We provide core technology with our equipments

3. We provide the most professional tech service

4. We have wealthy experience on SMT factory setup

5. We can solve any question about SMT

![]()

Contact:

CNSMT Electronics Equipment Co,.LTD

Email: info@smtlinemachine.com

www.smtlinemachine.com

Mb/whatsapp/wechat:+8613537875415

SKYPE:smtdwx