FUJI NXT Complete Nozzle Exchange Station UL03400 SMT Machine Spare Parts

-

Highlight

UL03400 SMT Machine Spare Parts

,FUJI NXT Nozzle Exchange Station

,UL03400 Nozzle Exchange Station

-

BRANDFUJI

-

ModelFUJIUL03400 NXT Complete Nozzle Exchange Station

-

CAPACITY1009

-

Mounter Weight0.79kg

-

Mounter Size56

-

SupplierCNSMT

-

ConditionNew

-

Place of OriginJapan

-

Brand NameFUJI

-

CertificationYAMAHA Vibration Vibration Fit YV YS

-

Model NumberFUJIUL03400 NXT complete nozzle exchange station

-

Minimum Order Quantity1

-

Pricenegotiation

-

Packaging DetailsWoodenbox

-

Delivery Time1-2 work days

-

Payment TermsT/T,Western Union,paypal

-

Supply Ability10pcs/day

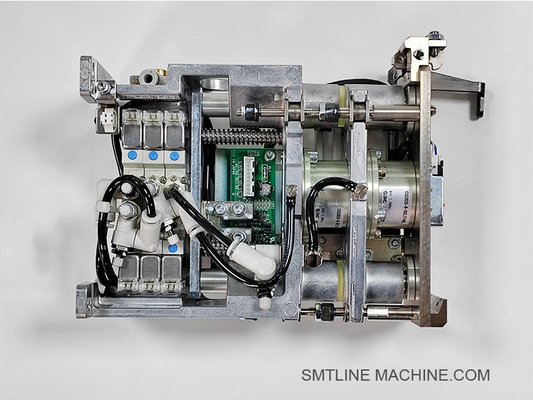

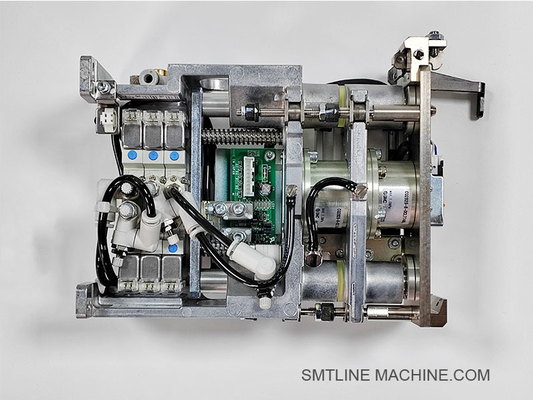

FUJI NXT Complete Nozzle Exchange Station UL03400 SMT Machine Spare Parts

FUJIUL03400 NXT complete nozzle exchange station

Our company has been in operation for 11 years and will definitely be your best choice with guaranteed quality and fast delivery

FUJI UL03400 – NXT Complete Nozzle Exchange Station

Overview

The FUJI UL03400 is a complete nozzle exchange station designed for use in FUJI NXT series SMT placement machines. It enables the automatic exchange, storage, and management of nozzles used on high-speed working heads (e.g., H12, H24, V12). This component plays a critical role in ensuring uninterrupted, flexible production with quick transitions between nozzle types.

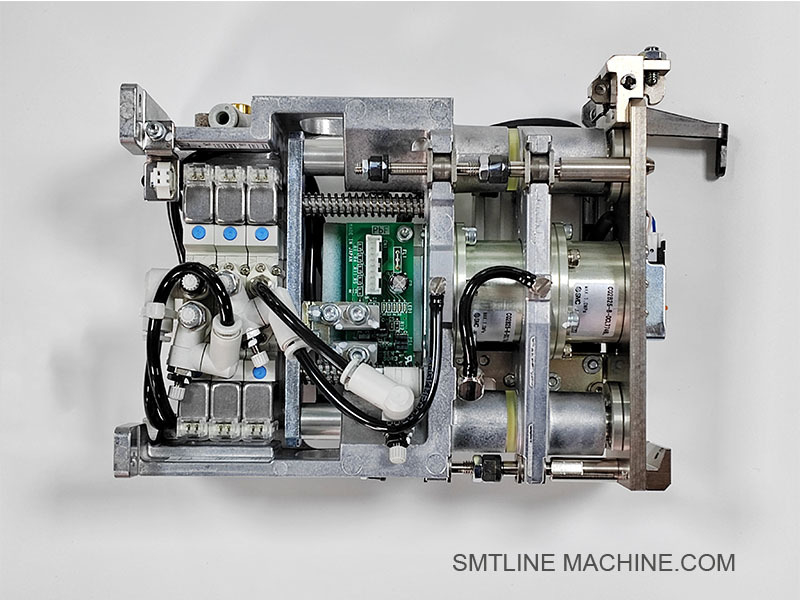

Key Features

Automated nozzle replacement without manual intervention

Integrated nozzle bank for storing multiple nozzle types

Supports various nozzle sizes and types (e.g., 0.4mm to 7.0mm)

Precisely engineered for repeatable and secure nozzle pickup/drop-off

Works in sync with FUJI’s control software for intelligent nozzle management

Applications

Compatible with FUJI NXT I, II, III, and IV platforms

Used in production lines with frequent product changeovers or multi-type component assembly

Ideal for heads like V12, H08, H12, H24, and H24S

Technical Specifications (Typical)

| Parameter | Specification |

| Part Number | UL03400 |

| Supported Nozzle Types | 3xx, 5xx, 7xx, 1xxx, and custom types |

| Storage Capacity | Typically 6–12 nozzles (varies by configuration) |

| Mounting Position | Fixed inside NXT module |

| Operating Interface | Controlled via NXT system software |

| Maintenance Requirement | Low (cleaning, occasional sensor calibration) |

Product Advantages

Enables fast nozzle changes for multi-component jobs

Minimizes downtime and maximizes placement efficiency

Reduces manual handling, minimizing nozzle contamination or damage

Fully integrated with nozzle life tracking and error prevention

Related Components

| Component | Part Number | Description |

| Nozzle Bank Unit | XM02345 / XM02160 | Holds spare nozzles for exchange |

| Nozzle Pickup/Drop Mechanism | XM02400 | Mechanical interface with head nozzles |

| Detection Sensor (Presence/Align) | XM02512 / XM02610 | Confirms correct nozzle positioning |

| IPS Vision System (for alignment) | 2AGKHA000402 | Verifies nozzle integrity after pickup |

| Communication Cable | XH01230 / XH01370 | Connects the exchange station to the control unit |

Related Accessories – FUJI UL03400 Nozzle Exchange Station

| Component Name | Part Number (Example) | Description |

| Nozzle Bank / Tray Assembly | XM02345 / XM02160 | Holds spare nozzles in designated slots for automatic exchange |

| Nozzle Pickup/Drop Mechanism | XM02400 | Mechanically handles nozzle placement and removal from the working head |

| Nozzle Presence Sensor | XM02512 / XM02610 | Detects whether a nozzle is present in the tray slot or on the head |

| Nozzle Positioning Guide Plate | XM02093 / XM02281 | Ensures precise alignment between head and nozzle bank |

| Sensor Control PCB | XK04210 | Interfaces with sensors and sends signals to the main system |

| Communication Cable / Harness | XH01230 / XH01320 | Connects the nozzle station to the controller for power and data transfer |

| Mounting Frame / Bracket | XM02700 | Structural support for fixing the station inside the NXT module |

| Nozzle Clamp Assembly | XM02690 | Mechanism that securely holds the nozzle during pickup and placement |

| Nozzle ID Detection Sensor | XM02800 / XM02940 | Optional unit to read nozzle ID or type automatically |

Optional Accessories / Spare Parts

| Accessory | Function |

| Anti-static Nozzle Tray Cover | Protects nozzles from dust and static discharge |

| Nozzle Tray Cleaning Tool | For cleaning nozzle tray pockets to ensure smooth exchange |

| Diagnostic LED Panel | Indicates exchange status and errors (if equipped) |

![]()

FAQ Guide – FUJI UL03400 NXT Complete Nozzle Exchange Station

General Information

Q1: What is the FUJI UL03400 Nozzle Exchange Station used for?

A: The UL03400 is a fully automated nozzle exchange unit installed in FUJI NXT SMT machines. It allows the working head (e.g., H12, V12, H24) to automatically pick up and return nozzles during production, enabling quick changes between different nozzle types without operator intervention.

Q2: Which FUJI machines support UL03400?

A:

FUJI NXT I, II, III, and IV series machines

Commonly used with H08, H12, H24, and V12 working heads

Requires machine software to support nozzle management

Functionality & Features

Q3: How many nozzles can it hold?

A:

Typically supports 6 to 12 nozzles, depending on the tray configuration and head type.

Q4: How does the exchange process work?

A:

1. The head aligns with the nozzle bank.

2. The nozzle is dropped off or picked up using the nozzle clamp mechanism.

3. Sensors confirm the nozzle’s presence and correct positioning.

4. The machine logs the nozzle ID and continues production seamlessly.

Q5: Is nozzle recognition supported?

A:

Yes, optional sensors or vision systems can verify nozzle presence, type, and alignment.

Maintenance & Troubleshooting

Q6: What maintenance does UL03400 require?

A:

Regular cleaning of nozzle slots to prevent misplacement

Sensor checks (presence/position)

Cable connection inspections

Periodic recalibration of tray alignment

Q7: What are common failure signs?

| Symptom | Possible Cause | Suggested Action |

| Nozzle not picked up | Dirty or misaligned tray | Clean and recalibrate nozzle tray |

| "Nozzle not present" alarm | Faulty presence sensor or disconnection | Check and test sensor wiring |

| Incorrect nozzle installed | Wrong tray position or ID read failure | Verify tray mapping and sensor calibration |

| Slow exchange time | Friction in pickup mechanism | Lubricate or inspect clamp parts |

Related Components

| Component | Part Number (Example) | Function |

| Nozzle Tray Bank | XM02345 / XM02160 | Holds spare nozzles for head exchange |

| Nozzle Clamp Unit | XM02690 | Mechanically secures the nozzle |

| Presence Detection Sensor | XM02512 / XM02610 | Confirms nozzle is in place |

| Vision Processing Board | 2AGKHA000402 | Used for image-based nozzle checks (optional) |

| Cable Harness | XH01230 / XH01370 | Power and signal transmission |

Best Practices

Always use FUJI original nozzles and trays for guaranteed fit

Clean nozzle slots with air and lint-free wipes weekly

Keep track of nozzle wear using system monitoring tools

Ensure proper tray mapping and head calibration after part changes

Do not manually move the nozzle tray while powered

We can do for you:

1. We provide fulL SMT solution for you

2. We provide core technology with our equipments

3. We provide the most professional tech service

4. We have wealthy experience on SMT factory setup

5. We can solve any question about SMT

![]()

Contact:

CNSMT Electronics Equipment Co,.LTD

Email: info@smtlinemachine.com

www.smtlinemachine.com

Mb/whatsapp/wechat:+8613537875415

SKYPE:smtdwx