-

Highlight

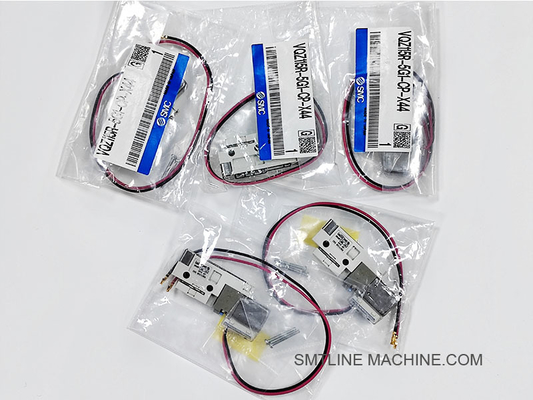

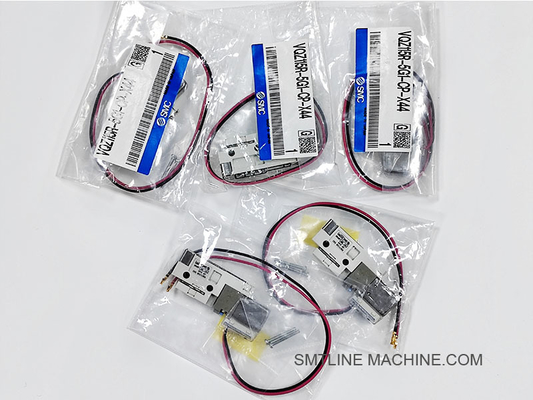

FUJI working head solenoid valve

,H12HSH08H04 Solenoid Valve

,SMT Spare Parts Solenoid Valve

-

BRANDFUJI

-

ModelFUJIXB03330 H12HSH08H04 Working Head Solenoid Valve

-

CAPACITY1009

-

Mounter Weight0.79kg

-

Mounter Size56

-

SupplierCNSMT

-

ConditionNew

-

Place of OriginJapan

-

Brand NameFUJI

-

CertificationYAMAHA Vibration Vibration Fit YV YS

-

Model NumberFUJIXB03330 H12HSH08H04 working head solenoid valve

-

Minimum Order Quantity1

-

Pricenegotiation

-

Packaging DetailsWoodenbox

-

Delivery Time1-2 work days

-

Payment TermsT/T,Western Union,paypal

-

Supply Ability10pcs/day

FUJI XB03330 H12HSH08H04 Working Head Solenoid Valve SMT Spare Parts

FUJIXB03330 H12HSH08H04 working head solenoid valve

Our company has been in operation for 11 years and will definitely be your best choice with guaranteed quality and fast delivery

FUJI XB03330 Solenoid Valve – For H12HS / H08 / H04 Working Heads

Product Overview

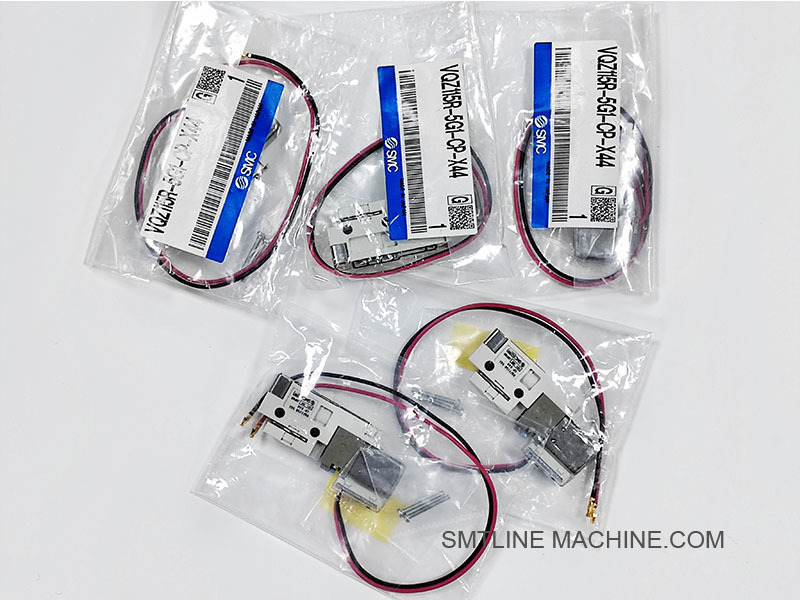

The FUJI XB03330 is an original solenoid valve specifically designed for the NXT series working heads, including H12HS, H08, and H04. It is a key pneumatic control component responsible for managing vacuum switching, suction, and release of components during the pick-and-place process.

Key Features

Enables vacuum ON/OFF control within the working head Millisecond-level fast response for high-speed placement Fully compatible with FUJI H12HS, H08, and H04 heads Long-life design with durable sealing and coil Original FUJI part with standard mounting and quick-connect ports

Applications

Used in FUJI NXT-series SMT machines

Controls nozzle suction, blow-off, and vacuum release

Works with vacuum sensors and pressure regulators for closed-loop control

Installed inside the working head near the nozzle or vacuum manifold

Technical Specifications (Typical)

| Parameter | Specification |

| Rated Voltage | DC 24V (FUJI standard control voltage) |

| Response Time | ≤ 10 ms |

| Working Pressure | 0.3 – 0.6 MPa |

| Media Type | Clean, dry air (oil-free) |

| Port Type | M3 or φ4 push-in pneumatic fittings |

| Service Life | ≥ 10 million cycles |

Included in Package

1 × XB03330 Solenoid Valve (with coil)

FUJI original label and part ID

Mounting screws may vary by head model (check manual or BOM)

Product Benefits

The FUJI XB03330 Solenoid Valve is essential for ensuring stable component pickup and precise placement in high-speed SMT operations. Its reliability, compact size, and compatibility with multiple head types make it a preferred replacement part for maintenance and repair of NXT heads.

Related Accessories – FUJI XB03330 Solenoid Valve

| Component Name | Part Number (Example) | Function / Description |

| Solenoid Valve (Main Unit) | XB03330 | Controls vacuum ON/OFF inside the working head |

| Solenoid Coil Harness | XH01360 / XH01400 | Electrical cable that powers the solenoid coil |

| Vacuum Tube / Air Hose | XM02113 / XM01897 | Pneumatic tubing that connects valve to vacuum manifold/nozzle |

| Push-in Pneumatic Fittings | XM01941 / XM02225 | Connectors for air tubing (M3 or 4mm ID hose types) |

| Vacuum Sensor | XB02200 / XB03360 | Detects vacuum level after solenoid actuation |

| Working Head Manifold Block | XM01184 / XM01953 | Distributes vacuum/air to different valve lines in the head |

| Nozzle Shaft Assembly | XH00905 / XM01345 | Final vacuum path from solenoid to suction nozzle |

| Exhaust Muffler | XB02490 / XB01107 | Silences air released by the valve |

| Mounting Screws / Gaskets | XM02690 / XM01472 | Hardware for securing valve to internal manifold or bracket |

| Valve Support Bracket | XM01275 / XM02244 | Mechanically secures the solenoid valve inside the working head |

Head Type Compatibility (Cross-Reference)

| Head Type | Typical Quantity per Head | Used For |

| H12HS | 6–12 | One per nozzle or zone |

| H08 | 4–8 | Dual-nozzle vacuum control |

| H04 | 4 | Single-nozzle setups |

> Always match solenoid specs to head model and firmware settings to ensure proper operation.

FUJI XB03330 Solenoid Valve – Related Part Numbers

| Component Name | Part Number | Description |

| Solenoid Valve (Main Unit) | XB03330 | Controls vacuum ON/OFF in the working head |

| Solenoid Coil Harness | XH01400 / XH01360 | Electrical cable that powers the solenoid coil |

| Vacuum Sensor | XB03360 / XB02200 | Monitors vacuum level during component pick-up |

| Pneumatic Fittings (Push-in) | XM01941 / XM02225 | Connectors for 3mm/4mm air tubing to the solenoid valve |

| Air Tube / Vacuum Hose | XM01897 / XM02113 | Connects the valve to vacuum sources and nozzles |

| Exhaust Muffler | XB01107 / XB02490 | Reduces noise from the solenoid exhaust ports |

| Mounting Bracket / Support | XM02244 / XM01275 | Mechanical support for securing the valve inside the head |

| Seals / Gaskets | XM01472 / XM02690 | Used during valve installation to prevent air leakage |

| Vacuum Distribution Manifold | XM01184 / XM01953 | Directs air from one source to multiple solenoids or nozzles |

| Nozzle Shaft Assembly | XH00905 / XM01345 | Final vacuum path leading to the suction nozzle |

Alternative / Cross-Compatible Parts (Check before use)

| Purpose | Compatible Part Numbers | Remarks |

| Small universal solenoid valves | SMC VQ110U / CKD 2JB series | Non-FUJI options, for third-party retrofits |

| Alternate valve wiring harness | XH01391 / XH01231 | May differ in length or connector; verify specs |

Notes:

The XB03330 valve is specifically tuned for use inside FUJI NXT working heads; substitutes should match voltage, port size, and actuation speed.

Always confirm compatibility based on machine series, head type, and pneumatic system configuration.

![]()

FAQ Guide – FUJI XB03330 H12HS / H08 / H04 Working Head Solenoid Valve

General Information

Q1:What is the FUJI XB03330 Solenoid Valve used for?

A:

TheXB03330 is a high-speed solenoid valve installed inFUJI NXT working heads (H12HS, H08, H04). It controlsvacuum switching, enabling the nozzle topick up or release components by rapidly turning air suction on or off.

Q2:Which FUJI heads use this valve?

A:

The XB03330 is commonly used in:

H12HS – 12-nozzle high-speed head

H08 – 8-nozzle standard head

H04 – 4-nozzle precision head

The number of solenoids per head varies depending on nozzle configuration.

Functionality & Operation

Q3:What does the valve control exactly?

A:

It regulates compressed air to control:

Vacuum activation (for component pick-up)

Vacuum release / blow-off (to place or discard components)

Air channel switching for different nozzle actions

Q4:How fast does the XB03330 respond?

A:

Response time is typically≤ 10 milliseconds, allowing fast pick-and-place cycles at high machine throughput (20,000+ CPH depending on head type).

Q5:Can I use third-party solenoid valves as replacements?

A:

Not recommended. While some industrial solenoid valves may fit physically (e.g., from SMC or CKD), they oftendo not meet FUJI’s exact voltage, flow, timing, or mounting requirements. Use only FUJI-certified parts for best performance and machine safety.

Installation & Maintenance

Q6:Where is the XB03330 installed?

A:

Inside theNXT working head, typically mounted on or near thepneumatic manifold. It is connected viapush-in air fittings and anelectrical cable (e.g., XH01400).

Q7:Do I need to calibrate the head after valve replacement?

A:

No calibration is usually needed, but it is recommended to:

Run avacuum check for all nozzles

Verifycomponent pick-up accuracy

Ensure valve response and airflow are stable

Q8:What is the expected service life?

A:

The XB03330 is rated for10 million+ cycles under normal SMT operating conditions. Replace it if:

Vacuum performance is inconsistent

Response time increases

Internal coil or spring fails

Troubleshooting

| Issue | Possible Cause | Recommended Action |

| No suction on nozzle | Faulty solenoid valve | Check/reseat or replace XB03330 |

| Delayed or failed component release | Valve not opening properly | Clean or replace valve |

| Nozzle vacuum fluctuates | Air leak or valve seal failure | Check air tubing and valve seals |

| Electrical error from valve circuit | Coil failure or wiring issue | Test continuity; replace harness or valve |

Related Parts

| Component | Part Number | Purpose |

| Solenoid Valve | XB03330 | Main vacuum control valve |

| Coil Cable Harness | XH01400 / XH01360 | Powers the valve |

| Pneumatic Fittings | XM01941 / XM02225 | Air tube connectors |

| Vacuum Tubing | XM01897 / XM02113 | Connects valve to manifold/nozzles |

| Vacuum Sensor | XB03360 / XB02200 | Detects suction status |

| Mounting Bracket | XM02244 / XM01275 | Holds the valve inside the head |

Best Practices

Useclean, dry, oil-free air to avoid valve contamination

Avoid bending or kinking air tubes connected to the valve

Always replace valves withoriginal FUJI parts

Inspect valves during scheduled head maintenance intervals

Summary

TheFUJI XB03330 solenoid valve is a critical component in the NXT head's pneumatic system, ensuring high-speed and precise component handling. Regular inspection and proper replacement will maintain machine reliability and placement quality.

We can do for you:

1. We provide fulL SMT solution for you

2. We provide core technology with our equipments

3. We provide the most professional tech service

4. We have wealthy experience on SMT factory setup

5. We can solve any question about SMT

![]()

Contact:

CNSMT Electronics Equipment Co,.LTD

Email: info@smtlinemachine.com

www.smtlinemachine.com

Mb/whatsapp/wechat:+8613537875415

SKYPE:smtdwx