-

Highlight

FUJI NXT nozzle exchange station

,Nozzle Exchange Station UL03400

,UL03400 SMT Spare Parts

-

BRANDFUJI

-

ModelFUJIUL03400 NXT Complete Nozzle Exchange Station

-

CAPACITY1009

-

Mounter Weight0.79kg

-

Mounter Size56

-

SupplierCNSMT

-

ConditionNew

-

Place of OriginJapan

-

Brand NameFUJI

-

CertificationYAMAHA Vibration Vibration Fit YV YS

-

Model NumberFUJIUL03400 NXT complete nozzle exchange station

-

Minimum Order Quantity1

-

Pricenegotiation

-

Packaging DetailsWoodenbox

-

Delivery Time1-2 work days

-

Payment TermsT/T,Western Union,paypal

-

Supply Ability10pcs/day

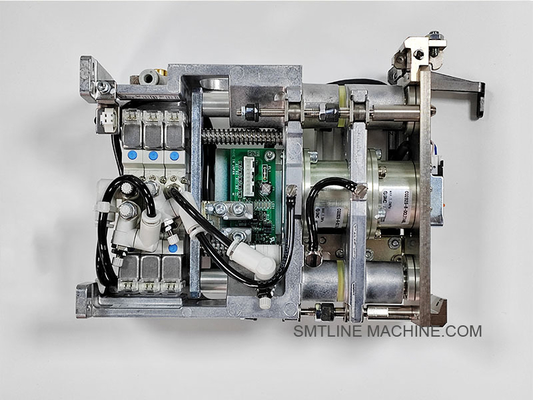

FUJI NXT Complete Nozzle Exchange Station UL03400 SMT Spare Parts

FUJIUL03400 NXT complete nozzle exchange station

Our company has been in operation for 11 years and will definitely be your best choice with guaranteed quality and fast delivery

FUJI UL03400 NXT Complete Nozzle Exchange Station – Product Description

Overview

The FUJI UL03400 is a fully automated nozzle exchange station designed for use with FUJI NXT series SMT placement machines. It enables the working head to automatically change nozzles during operation without manual intervention, improving production flexibility, efficiency, and reducing downtime.

Key Features

Supports automatic nozzle change during live production.

Designed to hold and organize multiple nozzle types for different components.

Features precise mechanical alignment for secure insertion and removal.

Integrates with the machine’s nozzle ID recognition system (e.g., code pins or sensors).

Rugged and durable construction for high-frequency nozzle changes.

Easy maintenance and replacement of trays or nozzle racks.

Applicable Machines

FUJI NXT I / NXT II / NXT III modules

Compatible with working heads:

H04, H08, H12HS, V12, H24, etc.

> The number of exchange stations per module depends on machine layout and nozzle change strategy.

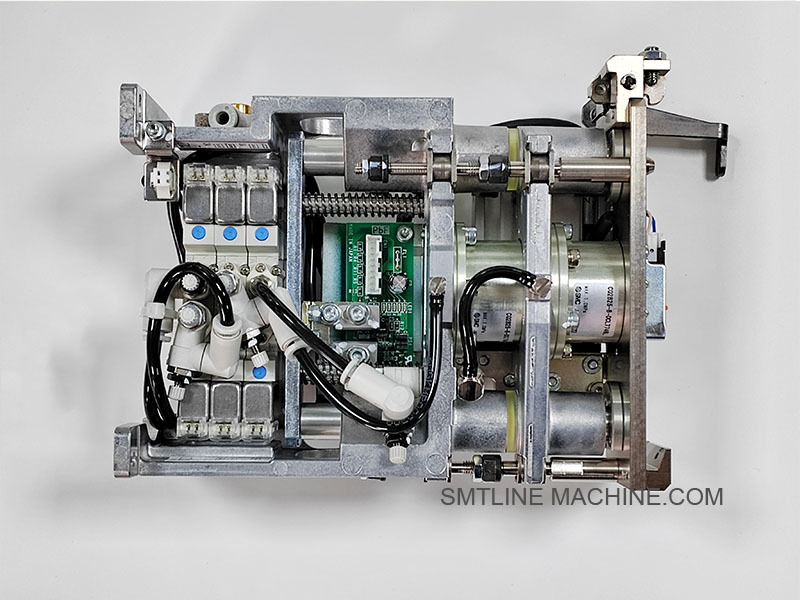

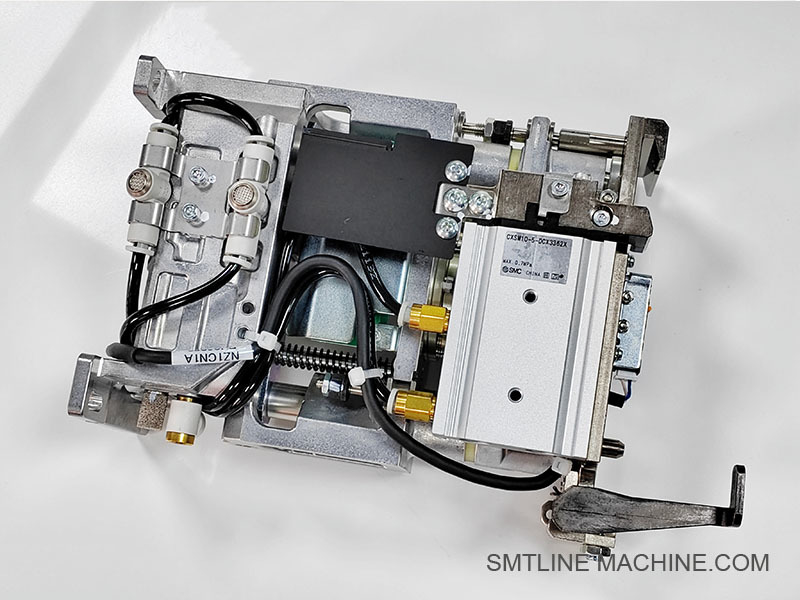

Structure and Components

| Component | Description |

| Nozzle Tray | Holds multiple nozzles in fixed positions for automatic access |

| Identification System | Includes nozzle ID pins or encoding features for recognition |

| Protective Cover | Prevents dust or foreign objects from entering the station |

| Mounting Hardware | Attaches the exchange station to the machine frame or rail |

Related Parts & Accessories

| Name | Part Number (Example) | Description |

| Complete Nozzle Station Body | UL03400 | Main structure with base and alignment hardware |

| Nozzle Tray Assembly | UL03401 | Detachable tray used to hold multiple nozzles |

| Nozzle ID Pin Set | UL03402 | Pin code for identifying nozzle type in each slot |

| Dust Cover / Protection Cap | UL03403 | Protects nozzles and slots from contamination |

| Compatible Nozzles | AA05W1, AA06Z1, AA07C1 | Common nozzle models used for various component types |

Maintenance Tips

Clean trays regularly to prevent nozzle jam or misalignment.

Check identification pins for wear to ensure correct nozzle detection.

Replace trays or protective covers if damaged or deformed.

Verify mounting screws remain tight to ensure positional accuracy.

Summary

The FUJI UL03400 Nozzle Exchange Station is a critical automation component in FUJI NXT SMT lines, enabling seamless, automatic nozzle changes. It reduces manual workload, boosts efficiency, and ensures consistent, high-speed production across diverse product types.

Related Accessories – FUJI UL03400 Nozzle Exchange Station

| Component Name | Part Number (Example) | Description |

| Nozzle Exchange Tray | UL03401 | Removable tray that holds multiple nozzles in precise alignment slots |

| Nozzle Identification Pin Set | UL03402 | ID pins or encoding columns for nozzle type recognition by the system |

| Protective Cover / Dust Shield | UL03403 | Plastic or metal shield to prevent contamination inside the tray station |

| Tray Spring/Lock Mechanism | UL03404 | Mechanical parts that hold and stabilize the tray and ensure proper nozzle docking |

| Tray Mounting Brackets | UL03405 | Metal parts used to mount the tray to the NXT machine module |

| Anti-static Tray Insert | UL03406 | ESD-safe tray liners or inserts to protect sensitive nozzles |

| Tray Alignment Guide Pins | UL03407 | Ensures exact mechanical alignment between tray slots and nozzle insertion head |

| Tray Detection Sensor (if equipped) | UL03408 | Optional sensor used to confirm tray presence or tray ID |

| Tray Fastening Screws/Hardware | UL03409 | Set of screws and fasteners for securing tray station to the machine frame |

| Nozzle Reference Nozzles | AA05W1, AA06Z1, AA07C1 etc. | Actual nozzles stored in the exchange station for automatic switching |

Usage Notes:

Thetray (UL03401)is the core removable element — each one can hold a specific set of nozzles.

TheID pin set (UL03402)ensures each nozzle slot is recognized accurately by the machine.

Protective elements likedust shields and anti-static insertshelp maintain nozzle integrity in high-volume production.

If your NXT line changes nozzle types frequently or handles sensitive parts, these accessories arehighly recommended.

FUJI UL03400 Nozzle Exchange Station – Related Part Numbers

| Component Name | Part Number | Description |

| Nozzle Exchange Station Body | UL03400 | Main body for the NXT automatic nozzle exchange unit |

| Nozzle Tray Assembly | UL03401 | Removable tray to hold multiple nozzles for automatic pick/change |

| Nozzle ID Pin Set (Coding Pegs) | UL03402 | Physical ID pins for nozzle type recognition in each tray slot |

| Tray Locking Spring / Latch Set | UL03404 | Mechanical parts that secure the tray in place to prevent misalignment |

| Protective Cover / Dust Shield | UL03403 | Prevents dust or foreign particles from entering the nozzle tray area |

| Tray Alignment Guide Pins | UL03407 | Ensures precise alignment between tray and nozzle change head |

| ESD-Safe Tray Insert (optional) | UL03406 | Anti-static liner for nozzles to prevent ESD damage |

| Mounting Bracket / Screw Set | UL03409 | Hardware used to mount the station onto the NXT machine frame |

| Tray Presence Detection Sensor | UL03408 | Optional sensor to detect presence or correct installation of nozzle tray |

Compatible Nozzles (Common Examples)

| Nozzle Type | Part Number | Compatible Heads |

| Nozzle #1 | AA05W1 | H04, H08 |

| Nozzle #2 | AA06Z1 | H12, H24 |

| Nozzle #3 | AA07C1 | V12 |

| Nozzle #4 | AA08F1 | High-precision chip components |

| Nozzle #5 | AA0A11 | Custom or odd-form component use |

Notes

All part numbers listed are official FUJI parts.

Custom trays can be configured based on specific nozzle models in use.

The number of trays and stations installed depends on the module configuration and nozzle change frequency.

![]()

FAQ Guide – FUJI UL03400 NXT Complete Nozzle Exchange Station

General Questions

Q1: What is the FUJI UL03400 Nozzle Exchange Station used for?

A:

The UL03400 is a fully automatic nozzle exchange station designed for FUJI NXT I, II, and III pick-and-place machines. It allows the placement head to automatically change nozzles during production, increasing efficiency and enabling flexible component handling.

Q2: Which machines is it compatible with?

A:

FUJI NXT I / NXT II / NXT III modules

Compatible with heads such as H04, H08, H12HS, H24, V12, etc.

Q3: How many nozzles can it hold?

A:

The number of nozzles it holds depends on the tray model (e.g., UL03401). Each tray typically contains multiple slots (6–10) for nozzles. Multiple trays can be used in one exchange station depending on the configuration.

Operation & Functionality

Q4: How does it work?

A:

The nozzle exchange station is mounted on the placement module. During operation, the head parks over the station, deposits the current nozzle into an empty slot, and picks up a new one as needed. The machine recognizes the nozzle type via ID pins or coding pegs.

Q5: Is the nozzle change process fully automatic?

A:

Yes. The entire nozzle change sequence is controlled by the machine’s software, requiring no manual interaction during production.

Q6: Does it support nozzle ID detection?

A:

Yes. It uses mechanical ID pins (UL03402) or integrated sensors to detect the nozzle type and confirm correct placement. The system logs the nozzle status in real time.

Installation & Maintenance

Q7: Where is the UL03400 installed?

A:

It is typically mounted on the frame rail or platform inside the FUJI NXT module, either at the front or rear, depending on the machine layout.

Q8: Is calibration required?

A:

Yes. After installation, the tray and nozzle positions must be calibrated via the machine’s control system to ensure precise pick-and-place movements.

Q9: How often should it be maintained?

A:

Clean the tray weekly or after every shift in dusty environments. Inspect ID pins and tray springs monthly for wear. Replace protective covers if damaged.

Troubleshooting

Q10: Common problems and solutions:

| Issue | Possible Cause | Solution |

| Nozzle not picked up correctly | Misaligned tray, worn guide pins | Recalibrate tray, replace guide pins |

| Nozzle ID not recognized | Dirty or worn ID pin | Clean or replace ID pin (UL03402) |

| Nozzle stuck during change | Tray slot obstruction, debris in tray | Clean tray thoroughly, check nozzle compatibility |

| Machine alarm during nozzle change | Sensor failure, ID mismatch | Check wiring, recalibrate nozzle data |

Related Parts Overview

| Part | Part Number | Function |

| Nozzle Exchange Station Body | UL03400 | Main unit for automatic nozzle change |

| Nozzle Tray Assembly | UL03401 | Holds multiple nozzles |

| Nozzle ID Pin Set | UL03402 | Identifies nozzle types in each slot |

| Protective Cover | UL03403 | Prevents dust contamination |

| Tray Locking Mechanism | UL03404 | Secures the tray inside the unit |

| Tray Alignment Guide Pins | UL03407 | Ensures precise nozzle insertion alignment |

Best Practices

Always use clean, undamaged nozzles in the tray. Confirm nozzle-to-tray mapping in the system software. Use genuine FUJI trays and accessories to prevent alignment errors. Keep a spare tray (UL03401) ready to reduce downtime.

Conclusion

The FUJI UL03400 Nozzle Exchange Station is an essential automation tool for high-mix, high-speed SMT lines using NXT machines. With proper installation, regular maintenance, and the correct accessories, it enables efficient, error-free nozzle changes that enhance productivity and placement accuracy.

We can do for you:

1. We provide fulL SMT solution for you

2. We provide core technology with our equipments

3. We provide the most professional tech service

4. We have wealthy experience on SMT factory setup

5. We can solve any question about SMT

![]()

Contact:

CNSMT Electronics Equipment Co,.LTD

Email: info@smtlinemachine.com

www.smtlinemachine.com

Mb/whatsapp/wechat:+8613537875415

SKYPE:smtdwx