-

BRANDFUJI

-

ModelFUJI2AGKHB008800 H12HS Working Head Motherboard

-

CAPACITY1009

-

Mounter Weight0.79kg

-

Mounter Size56

-

SupplierCNSMT

-

ConditionNew

-

Place of OriginJapan

-

Brand NameFUJI

-

CertificationYAMAHA Vibration Vibration Fit YV YS

-

Model NumberFUJI2AGKHB008800 H12HS working head motherboard

-

Minimum Order Quantity1

-

Pricenegotiation

-

Packaging DetailsWoodenbox

-

Delivery Time1-2 work days

-

Payment TermsT/T,Western Union,paypal

-

Supply Ability10pcs/day

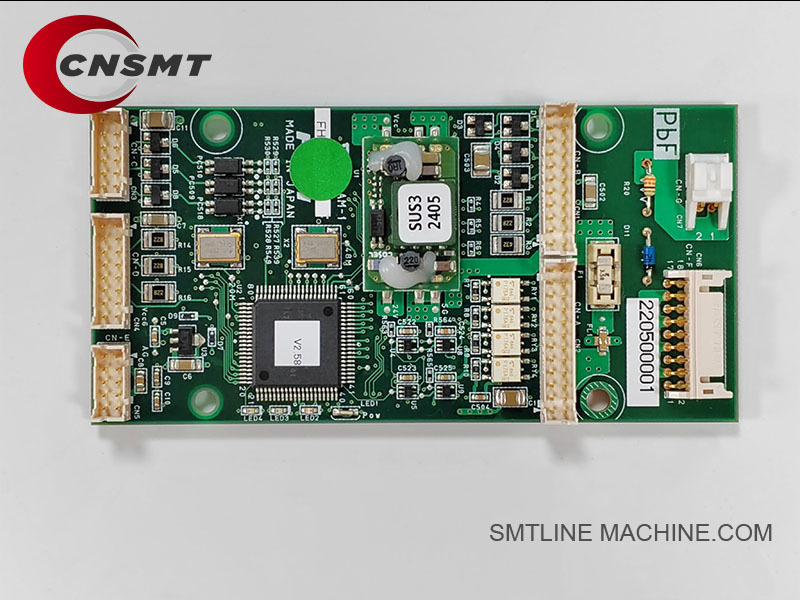

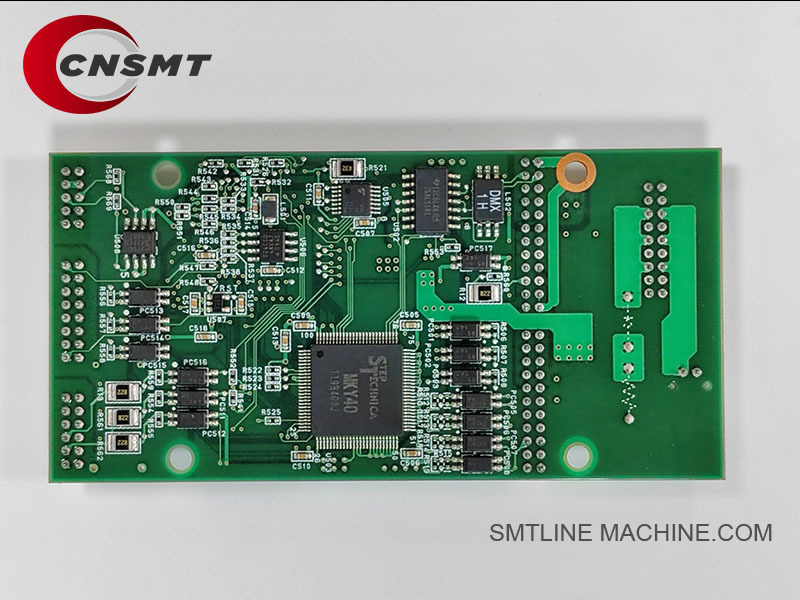

FUJI 2AGKHB008800 H12HS working head motherboard

FUJI 2AGKHB008800 H12HS working head motherboard

Our company has been in operation for 11 years and will definitely be your best choice with guaranteed quality and fast delivery

FUJI 2AGKHB008800 H12HS Working Head Motherboard – Product Description

Product Overview

The 2AGKHB008800 is the main control motherboard for the FUJI NXT H12HS working head. This PCB is the core electronic control unit that manages all operations of the H12HS head, including motion control, vacuum switching, signal processing, and communication with the machine's main control system. It plays a critical role in ensuring high-speed and high-precision pick-and-place performance.

Key Functions & Features

Controls all axes of the head (Z-axis, Theta rotation, and nozzle actuators).

Manages 12 nozzle vacuum systems, including vacuum/air pressure switching.

Processes feedback from pressure sensors, encoders, and motor positions.

Provides real-time control of pick-and-place movements with high precision.

Handles high-speed communication between the working head and the main machine controller.

Controls solenoid valves, sensors, and actuators inside the H12HS head.

Machine Compatibility

FUJI NXT II Series

FUJI NXT III Series

Machines equipped with the H12HS high-speed 12-nozzle head

Technical Specifications

| Item | Specification |

| Part Number | 2AGKHB008800 |

| Control Object | FUJI NXT H12HS working head |

| Power Supply | 24V DC (from main machine supply) |

| Communication Interface | High-speed serial communication with main controller |

| Main Functions | Motor control, vacuum management, sensor processing |

| Operating Temperature | 0–45°C, humidity <60%, non-corrosive environment |

| Installation | Embedded inside the H12HS working head (module type) |

Core Applications

Controls Z-axis lift movement and Theta rotation.

Manages vacuum detection and air pressure switching for all 12 nozzles.

Drives solenoid valves and pneumatic mechanisms.

Processes real-time feedback from vacuum pressure sensors to confirm pick status.

Ensures synchronous high-speed data exchange with the main controller for optimal performance.

Related Parts & Accessories

| Part Name | Part Number | Description |

| Pressure Sensor | XS00920 | Detects vacuum status for each nozzle |

| Pneumatic Mechanical Valve | XS03760 | Controls vacuum and air blow |

| Valve SPOOL (internal component) | XS03764 | Valve internal moving element |

| Signal Cable for Motherboard | XS02050 | Connects motherboard to main controller |

| Z-axis Lift Motor | 2AGGHA002700 | Controls up/down movement of nozzles |

| Theta Rotation Motor | 2AGGHA002800 | Controls rotation of nozzles |

| Cooling Fan for Motherboard | XH01431 | Maintains optimal temperature of motherboard |

Maintenance Recommendations

Inspect connectors and signal cables every 6–12 months.

Check the cooling system (ensure fans are working and free from dust).

Confirm proper function of vacuum sensors and pneumatic signals.

If symptoms like signal failure, communication error, or axis misbehavior occur, consider replacing the motherboard.

Summary

The FUJI 2AGKHB008800 H12HS Working Head Motherboard is the central control hub for the H12HS head, ensuring stable, high-speed, and precise operation. It is essential for maintaining the machine’s placement accuracy and production efficiency.

Related Accessories & Parts for FUJI 2AGKHB008800 H12HS Working Head Motherboard

| Part Name | Part Number | Description |

| Pressure Sensor | XS00920 | Detects nozzle vacuum status for pick confirmation |

| Mechanical Valve SPOOL | XS03764 | Internal spool component for air/vacuum valve |

| Mechanical Valve Body | XS03765 | Valve housing where the spool operates |

| Valve O-ring Kit | XS03766 | Sealing components for the mechanical valve |

| Valve Return Spring | XS03767 | Maintains spool position inside valve |

| Complete Pneumatic Valve Assembly | XS03760 | Full valve unit for vacuum/air control |

| Z-axis Lift Motor | 2AGGHA002700 | Controls vertical movement of the nozzle |

| Theta Rotation Motor | 2AGGHA002800 | Controls nozzle rotation movement |

| Nozzle Shaft Sleeve | XS01300 | Guide sleeve for nozzle lift movement |

| Nozzle Coupling Assembly | XS02100 | Mechanical connection for nozzle actuator |

| Motherboard Signal Cable | XS02050 | Connects motherboard to machine control unit |

| Power Cable for Motherboard | XS02051 | Provides power to the motherboard |

| Cooling Fan for Motherboard | XH01431 | Cools the motherboard inside the working head |

| Working Head Housing Assembly | XS05020 | Frame structure of the H12HS working head |

| Encoder for Z/Theta Axis | XS02410 | Position feedback sensor for lift and rotation |

Recommended Spare Kits

Valve maintenance kit (XS03764 + XS03765 + XS03766 + XS03767)

Sensor kit (XS00920 pressure sensor + cables)

Motor kit (2AGGHA002700 Z-axis + 2AGGHA002800 Theta motor)

Fan and cable kit (XH01431 cooling fan + XS02050/XS02051 cables)

Note:

These parts are directly related to the motherboard's control scope, including vacuum systems, motion control, sensors, and signal transmission within the H12HS working head.

Related Part Numbers for FUJI 2AGKHB008800 H12HS Working Head Motherboard

| Part Name | Part Number (PN) | Description |

| H12HS Working Head Motherboard | 2AGKHB008800 | Main control PCB for the H12HS head |

| Pressure Sensor | XS00920 | Vacuum detection sensor |

| Pneumatic Mechanical Valve | XS03760 | Complete air/vacuum control valve |

| Valve SPOOL (Internal) | XS03764 | Core moving component of the valve |

| Valve Body | XS03765 | Valve housing |

| Valve O-ring Set | XS03766 | Seal kit for valve |

| Valve Return Spring | XS03767 | Spring for spool return |

| Z-axis Lift Motor | 2AGGHA002700 | Controls nozzle up/down movement |

| Theta Rotation Motor | 2AGGHA002800 | Controls nozzle rotation |

| Nozzle Shaft Sleeve | XS01300 | Shaft guide for nozzle lift |

| Nozzle Coupling Assembly | XS02100 | Connects motor to nozzle mechanism |

| Signal Cable for Motherboard | XS02050 | Data connection between motherboard and machine |

| Power Supply Cable | XS02051 | Power cable for the motherboard |

| Cooling Fan for Motherboard | XH01431 | Maintains operating temperature |

| Working Head Frame/Housing | XS05020 | Structural housing of the H12HS head |

| Encoder for Z/Theta Axis | XS02410 | Provides position feedback for lift/rotation motors |

| Vacuum Tube Assembly | XS04125 | Air pathway between nozzles and valve/sensor |

| Air Filter | XS04120 | Removes contaminants from air supply |

Summary:

These part numbers are directly related to the functionality and maintenance of the 2AGKHB008800 H12HS Working Head Motherboard, covering vacuum systems, motion components, sensors, signal transmission, and structural elements.

![]()

FAQ Guide – FUJI 2AGKHB008800 H12HS Working Head Motherboard

General Information

Q1: What is the FUJI 2AGKHB008800 H12HS Working Head Motherboard?

A:

The 2AGKHB008800 motherboard is the core control circuit board inside the FUJI NXT H12HS working head. It is responsible for managing the head’s motors, sensors, vacuum system, and communication with the main machine controller. It ensures precise control for high-speed pick-and-place operations.

Functions & Applications

Q2: What does this motherboard control?

A:

Z-axis lift motors (up/down movement)

Theta rotation motors (nozzle rotation)

Vacuum and air pressure switching valves

Pressure sensors to confirm pickup status

Synchronizes head operations with the main control unit for accurate placement.

Q3: Which machines use the 2AGKHB008800 motherboard?

A:

FUJI NXT II Series

FUJI NXT III Series

Specifically for the H12HS high-speed 12-nozzle working head

Installation & Setup

Q4: How is the motherboard installed?

A:

Installed inside the H12HS working head housing.

Connected via signal cables (XS02050) and power cables (XS02051) to the main controller.

Interfaces with motors, pressure sensors (XS00920), valves (XS03760), and actuators.

Q5: Is calibration required after installation?

A:

No physical calibration needed.

The machine performs automatic recognition and initialization during startup.

Vacuum offset or pressure thresholds can be fine-tuned in machine settings if needed.

Troubleshooting & Common Issues

Q6: What are common failure symptoms?

A:

Communication errors with the head.

Z-axis or Theta motor malfunction.

Vacuum sensor reading failure or pick-up errors.

Nozzle control errors or stuck movements.

Complete head offline or failure to initialize.

Q7: What causes motherboard failure?

A:

Prolonged usage and electronic component fatigue.

Overvoltage or static discharge.

Moisture ingress or dust buildup.

Broken connectors or damaged wiring.

Malfunction of connected components (e.g., sensors, motors) can sometimes overload the board.

Maintenance Tips

Q8: How can I maintain the motherboard?

A:

Inspect and clean cooling fans (XH01431) regularly.

Check for loose cables or broken connectors.

Keep the working environment dry and dust-free.

Replace faulty sensors or motors promptly to prevent feedback errors.

Preventive replacement recommended after 3–5 years of continuous operation.

Replacement Guidelines

Q9: When should the motherboard be replaced?

A:

If there are repeated communication or initialization failures.

If multiple head component errors occur with no mechanical cause.

When electronic diagnostics indicate board-level faults.

Related Components

| Component | Part Number | Description |

| Pressure Sensor | XS00920 | Vacuum detection |

| Pneumatic Mechanical Valve | XS03760 | Controls vacuum/air |

| Z-axis Lift Motor | 2AGGHA002700 | Controls nozzle up/down |

| Theta Rotation Motor | 2AGGHA002800 | Controls nozzle rotation |

| Signal Cable | XS02050 | Data connection |

| Power Cable | XS02051 | Power supply line |

| Cooling Fan | XH01431 | Prevents overheating |

| Valve SPOOL | XS03764 | Valve internal moving part |

Ordering & Support Advice

Confirm compatibility with the machine and head model before ordering.

Usually ordered together with signal cables, cooling fans, and vacuum sensors for full head maintenance.

Available from FUJI official distributors or authorized SMT spare part suppliers.

Summary

The 2AGKHB008800 H12HS Working Head Motherboard is a critical control unit that manages all functions of the H12HS head in FUJI NXT machines. Regular maintenance and timely replacement are essential to maintaining high-speed, accurate production.

Related Products

We can do for you:

1. We provide fulL SMT solution for you

2. We provide core technology with our equipments

3. We provide the most professional tech service

4. We have wealthy experience on SMT factory setup

5. We can solve any question about SMT

![]()

Contact:

CNSMT Electronics Equipment Co,.LTD

Email: info@smtlinemachine.com

www.smtlinemachine.com

Mb/whatsapp/wechat:+8613537875415

SKYPE:smtdwx